Nicely : Supporting Your Sustainability Goals with Reliable Paper Slitter Rewinders

Customer Care 2024-05-02The landscape of the paper packaging and paper roll converting industry is undergoing a significant transformation, driven by the increasing demand for sustainable solutions towards paper materials that are biodegradable, recyclable, and reusable. This surge in demand marks a clear shift towards sustainability.

For instance, sustainable paper-based packaging alternatives are being developed in response to the global movement against single-use plastics. These alternatives often include materials such as kraft paper, cardboard, coated, or uncoated paperboard.

In this article, we will explore the paper applications that Nicely has catered to through a comparison table covering a broad range of paper roll slitting machines.

What Applications Do Nicely's Paper Slitter Rewinders Mainly Serve?

Here are some key applications where sustainable paper materials are being increasingly utilized

- Paper-based Packaging

- Labels and Tags

- Specialty Applications

For example, sustainable paper labels and Variable Information Print (VIP) thermal labels are increasingly preferred by consumers seeking eco-friendly options. These labels are commonly used in the e-commerce sector and for liner-free applications.

From packaging to electrical insulation and beyond, in today's paper roll converting industry, sustainable paper materials are reshaping industries and driving positive environmental change. With increasing emphasis on productivity, quality, and sustainability, our customers now more than ever rely on a solution-oriented provider to streamline their operations.

Enhancing Efficiency in Paper Converting Processes

To increase efficiency in paper converting processes, there are several key factors to consider. Nicely's clients often request specific features to meet their growing market demands :

1.Enlarging Unwind Capability and Durability:

Enhancing the unwind capability allows for smoother and longer production runs. It helps reduce downtime associated with roll changes and minimizes material waste. Durability is crucial to ensure the machinery withstands extended use and high production speeds. An example from our installations includes a roller width of 3200mm (10.5 ft), a maximum roll OD of 2500mm (8.2 ft), and a production speed of 1500 M/min (4921 ft/min).

2.Automatic Knife Positioning and Precision Slitting:

ensures precise and consistent slitting by eliminating the need for manual adjustments. With the ability to manage 10 sets of cutters in just 60-90 seconds, this automatic knife positioning feature significantly reduces setup time by at least 50% compared to regular blades setting and minimizes the risk of errors.

3.Advanced Control and Drive System:

Modern machinery control implementations, combined with a stable drive control system, enable high-speed slitting and rewinding of jumbo paper rolls. This greatly enhances production output and improves energy efficiency by around 30%. Advanced control systems also support automated paper processing through precise speed and tension control, ensuring optimal results in paper converting.

4.Automated Roll Handling:

Integration of multiple automations for end-of-the-line roll handling streamlines the unloading and packing processes, reducing the risk of potential hazards associated with manual adjustments.

Exploring Nicely's Paper Converting Solutions :

A Comparative Overview of Paper Slitter Rewinder

In the following comparison table, we will introduce the most frequently asked machine models categorized by Surface Winding Principle and Centre Winding Principle, along with their corresponding material applications.

Surface Winding Principle

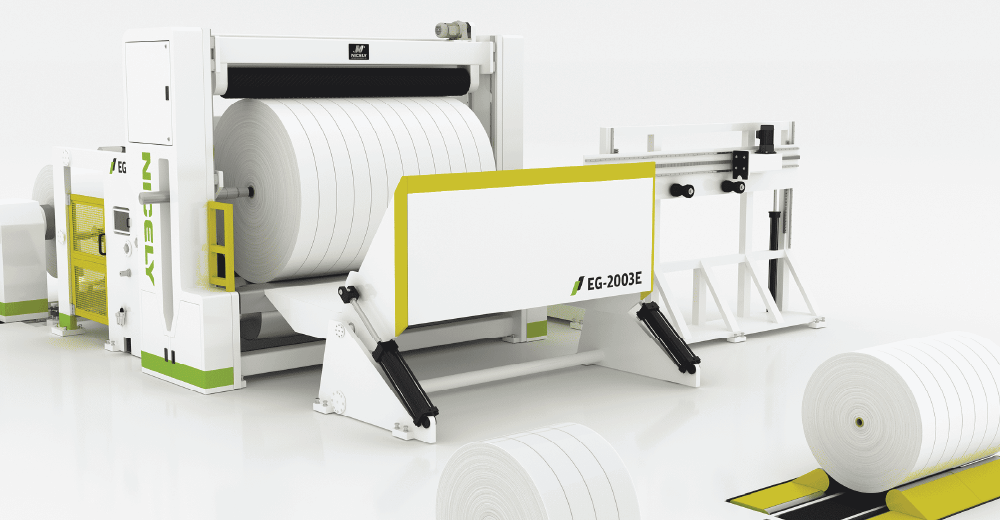

| EG-1N | EG-2 | EG-2003E |

|---|---|---|

|

|

|

|

Rewind OD : 300 mm (12”) Speed : 250 M/min (820ft/min) |

Rewind OD : 1200 mm (47”) Speed : 250 M/min (820ft/min) |

Rewind OD : 2500 mm (98”) Speed : 1500 M/min (4920 ft/min) |

| Single Surface Winding | Duplex Surface Winding | Shafted & Shaftless Surface Winding |

| Thermal paper roll & Linerless label | Kraft paper, Woodfree paper | Kraft paper, Coated & uncoated paper board |

| E-commerce labels | Tobacco paper | Food packaging, Paper tube |

Centre Winding Principle

| EG-4 | EG-7001 | EG-8002 |

|---|---|---|

|

|

|

|

Rewind OD : 1500 mm (59”) Speed : 600 M/min (1968ft/min) |

Rewind OD : 800 mm (31.4”) Speed : 600 M/min (1968ft/min) |

Rewind OD : 1500 mm (59”) Speed : 800 M/min (2624 ft/min) |

| Single Shaft Cantilever Center Winding Slitter | Duplex Shaft Turret Slitter Rewinder | Duplex Shaf Center Winding Slitter Rewinder |

| Specialty paper | Plotter, Printing paper, Specialty paper | Labels, Silicone paper |

| Insulation |

Food packaging Moisture Barrier |

Food Packaging Moisture Barrier |

Automation Options:

With a diverse range of machine types and configurations, the options for automation are plentiful. Depending on specific needs and preferences, these automation features ensure efficiency and productivity at every step of the process.

- Auto Core Loader

- Motorized Web Threading

- Shaftless Winding

- Auto Knife Positioning

- Auto Shaft Handling System

- Auto Tail Cut and Start-up

- Auto Roll Unloading / Handling / Conveying

- Advanced Control & Drive

Strength of Nicely's Paper Slitter Rewinders:

Versatility, Adaptability, Reliability -

It often happens that when we ask a new customer where they obtained information about Nicely, they mention being told, "When you need anything challenging, go to NICELY." This statement highlights the diverse solutions we currently provide, affirming Nicely’s dedication to evolving alongside our customers. From consumer-end products like linerless thermal rolls (EG-1N series) to upstream jumbo paper roll production (EG-2003E series) and middle-range food-related packaging (EG-8002 series), all of which are among our popular models. - Versatility.

From the above paper slitter comparison table, the key strength lies in our ability to provide tailored end-of-line solutions, aligning the trend towards replacing labor-intensive tasks with automated processes. Nicely understands the importance of streamlining the production line, from handling jumbo rolls to final packaging, therefore offers end-to-end solutions that ensure ease of operation and peace of mind for our customers. - Adaptability.

As demand for automatic slitting machines rises sharply in certain countries, numerous manufacturers flood the market, offering competitive pricing. However, amidst this intense competition, the critical question remains: what about the quality of service provided? Nicely's solid alliances with major players across industries say it all! - Reliability.

Related Article –

Upgrading Your Paper Slitter Rewinders for Sustainability

If investing in a new, efficient slitter raises concerns such as budget constraints or disruptions to current operations, Nicely strongly suggests considering the option to extend the capabilities of existing slitting machines through retrofitting. By upgrading discontinued or outdated components, you can significantly reduce maintenance costs while ensuring that your production remains aligned with market growth. This approach not only minimizes upfront investment but also contributes to sustainability by prolonging the lifespan of your equipment and reducing overall resource consumption.

Nicely is confident in helping customers save up to 50% of their investment budgets and substantial maintenance costs while assisting businesses in implementing environmental sustainability principles.

Related Articles –

Nicely continues to partner with customers for sustainable solutions in the paper converting industry, offering versatile, adaptable, and reliable paper roll slitter rewinders tailored to meet the evolving needs of customers. With a commitment to excellence and innovation, Nicely remains at the forefront of driving positive environmental change while delivering exceptional value to its clients.