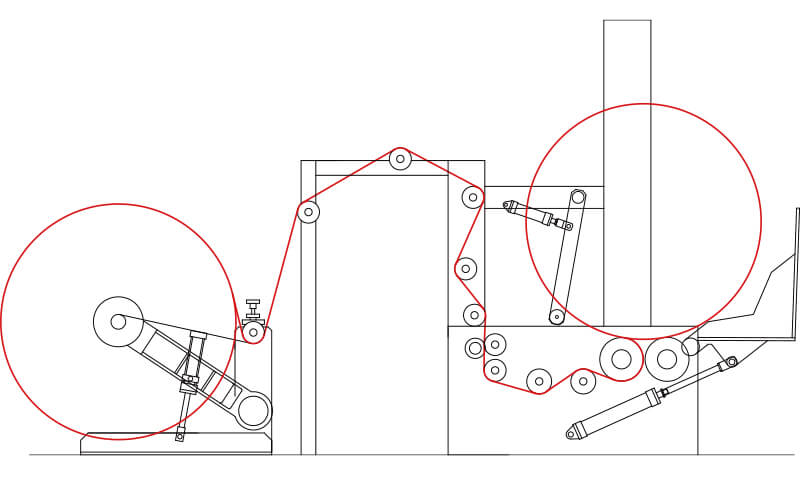

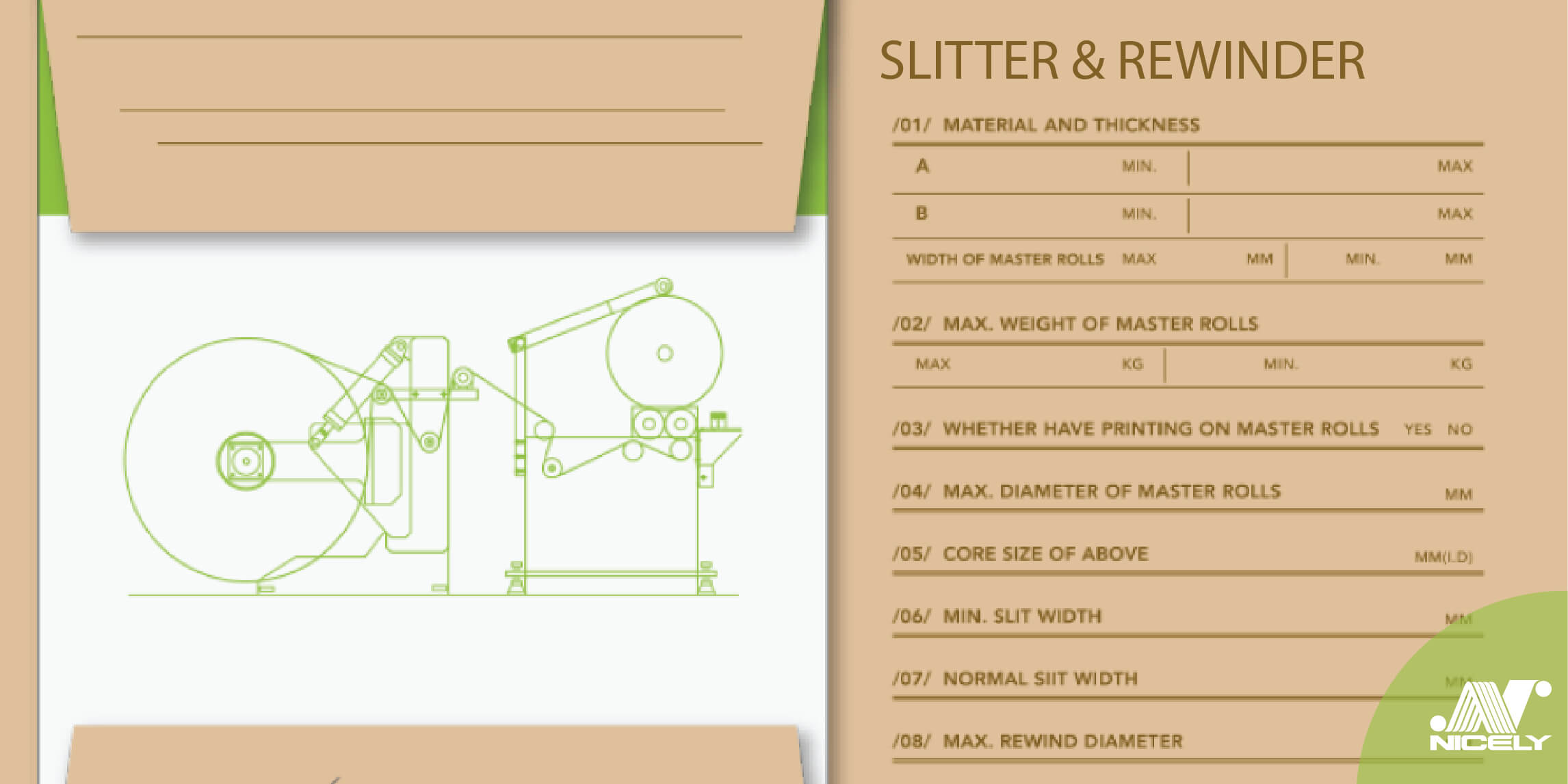

Single Shaft / Shaftless Surface Winding Slitter Rewinder

• Kraft paper / Liner

• Coated / uncoated Paper, board

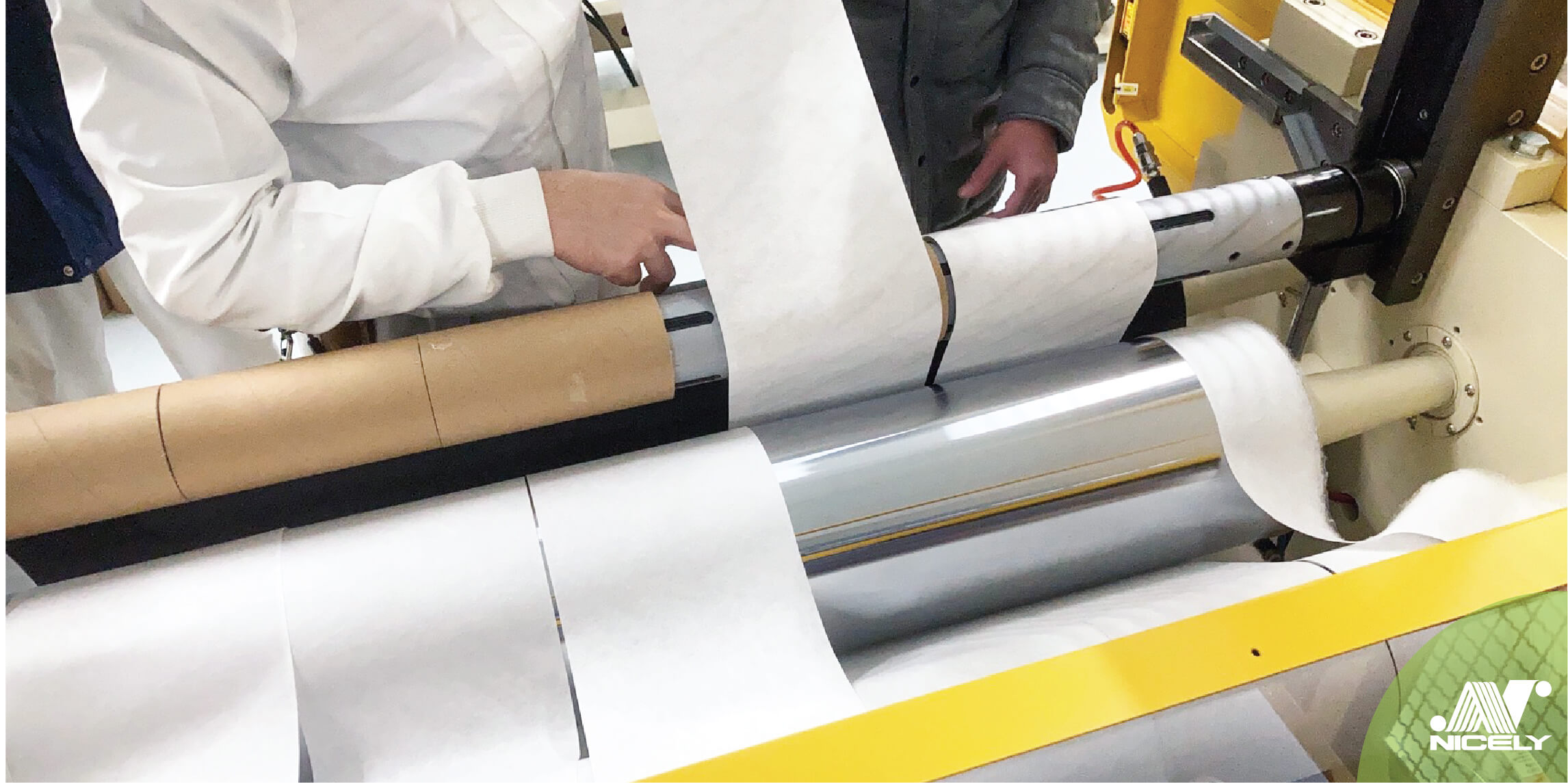

• Laminated paper / Aluminum foil / Metalized film

• Plain, Varnished, Embossed paper / 100% Recycled paper

• Cigarette paper

• Woodfree paper

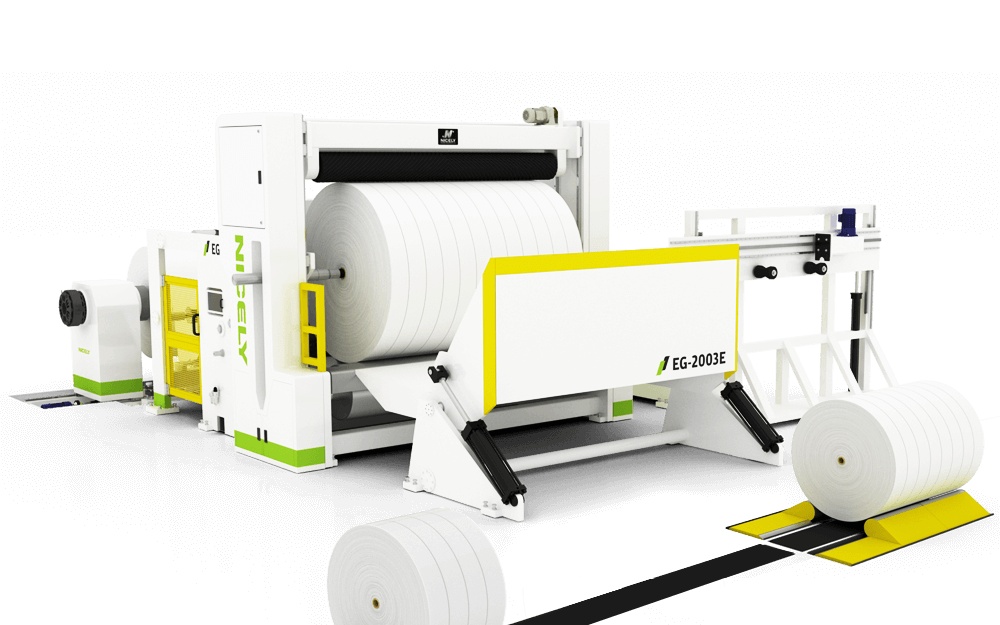

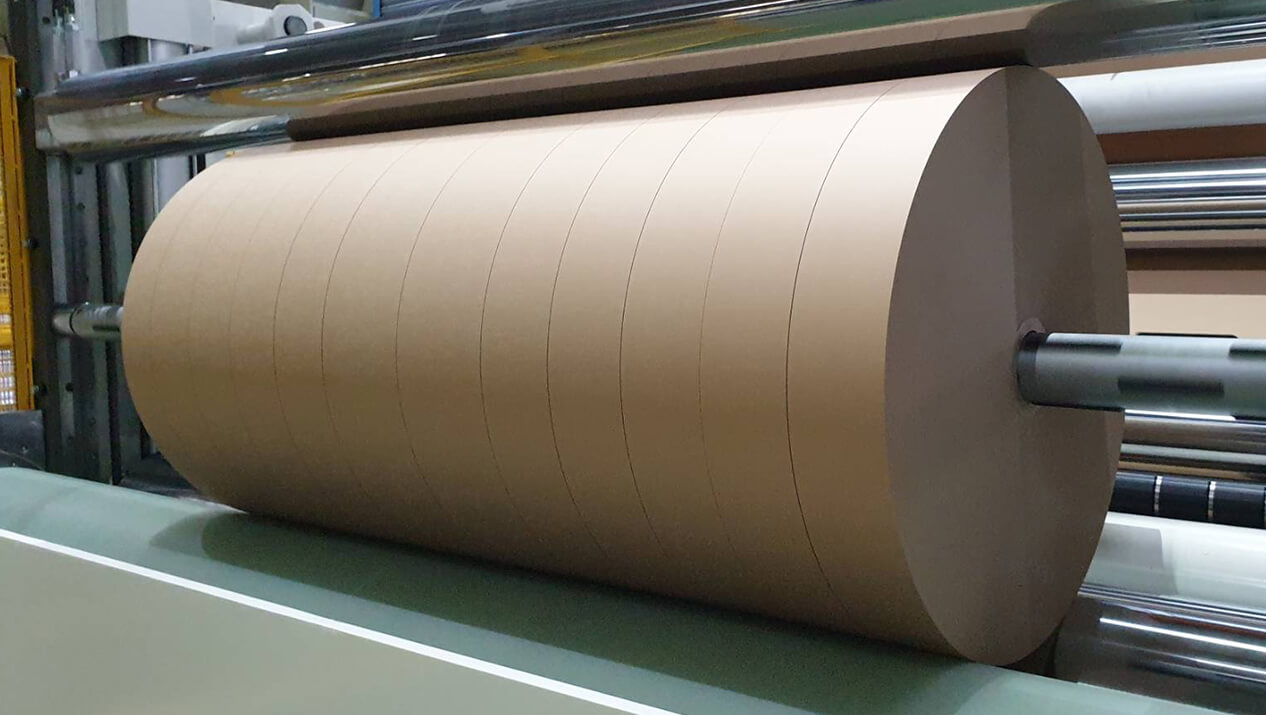

The cutting can be performed using either standard circular slitting blades or optional pneumatic cutters, offering flexibility in tool selection. Several optional functions, such as an automatic knife positioning, shaftless rewinding, and automatic roll pusher are available to enhance productivity and reduce labor intensity. A customized roll handling and packaging system can be configured according to the customer's production floorplan.

Standard Features

- Shaftless unwind stand.

- Circular shear slitting.

- Trim waste air blower.

- Top rider roller.

- Finished roll pusher.

- PLC control system incorporate with HMI touch screen.

- Enhanced shaftless unwind stand.

- Motorized web threading.

- Pneumatic cutter set.

- Auto. Knife positioning.

- Trim suction blower with crusher.

- Shaft handling system.

- Enhanced fencing & safety implements.

| Roller width | 1500 – 3200 mm |

|---|---|

| Unwind diameter | 1200 – 2200 mm |

| Min. slit width | 50 mm and up |

| Rewind diameter | 1200 – 2200 mm |

| Machine Speed | 400 / 600 / 800 M/min |

* Other specifications are offered at request.

The landscape of the paper packaging and paper roll converting industry is undergoing a significant transformation, driven by the increasing demand for sustainable solutions towards paper materials that are biodegradable, recyclable, and reusable. This surge in demand marks a clear shift towards sustainability.

In 2023, manufacturers worldwide experienced lower-than-expected economic conditions, with stagnant market inventories and hindered investment momentum. Notably, the only accelerating trend is the global demand for environmental sustainability and carbon reduction.

In November, Nicely delivered an EG-8002 Duplex Shaft Center Winding Slitter Rewinder, designed for slitting PE-coated paper and food packaging applications. This marks the fourth equipment supplied to our client, a leading supplier in Taiwan's food paper packaging sector.

Are you in search of the ideal slitter rewinder to effectively slit and rewind your materials? Slitter rewinders play a crucial role in converting large rolls into various sizes, aligning with market demands. Selecting the right machine can significantly enhance your production process. This informative article provides you with comprehensive insights to help you make an informed decision when choosing a slitter rewinder. Keep reading to learn the key factors to consider and the essential information to communicate with the manufacturer before requesting a quote.

Establish a Regular Maintenance Schedule, Keep the Machine Clean and Lubricated, Check the Tension and Alignment of the Web, Monitor the Blade Sharpness and Wear, and Diagnose and Troubleshoot Issues Promptly.

Nicely Machinery provides retrofitting and upgrading services for customers who have older slitter rewinders, whether machines were originally from Nicely or another supplier.