Training

While Nicely Slitters are commercialized globally, our technical support reaches out to customers efficiently to ensure the machine users are well trained and confident to approach full production.

Our after-sales training creates strong bond between personnel safety and quality performance, therefore, Nicely is rather emphasize the importance of the operation guidelines. After machine is delivered to customer’s facility, Nicely teams will come along to help with machine installation, a completed operation training will be put in action subsequently by our expertise to ensure the machine users are thoroughly trained to understand the safety guidance and skills for operating the machine.

Customer Supports

While Nicely Slitters are commercialized globally, our technical support reaches out to customers efficiently to ensure the machine users are well trained and confident to approach full production.

Besides on-site customer service, Nicely also provides flexible support remotely through an upgraded SIMATIC controller which enables Nicely technical team to diagnose and correct operation issues instantly.

SERVICES, appreciated by customers.

From the machine on-site trial before shipment, preparing for the delivery, commissioning at customer’s firm, or even the service hot-line, customer’s satisfaction of machine performance is the top priority of the entire Nicely team. Customers feel it too !

“Nicely service teams are often praised by customer’s production leaders for our high-quality cutting results and excellent control in tension made by coherent system operation. Our service team is highly skilled for the real-time support or remote support via digital communications to troubleshoot abnormalities immediately, which is so appreciated and supportive! "says a front-line service engineer.

Remote support

Remote technical support.

When traveling restriction was in place, Nicely Technical Team, including electrical and mechanical specialists, grouped up right on the spot to remotely help customers troubleshoot to resume customers ‘production seamlessly.

Maintenance

A time-based inspection on a machine is especially significant as efficient performance and high productivity are closely related to.

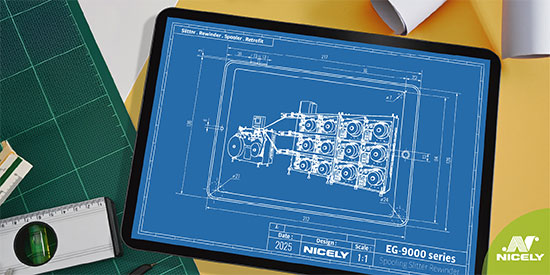

In order to make machine users obtain operation knowledge easily, our operation manual covers operation instructions, importance notice for handling the machine, lubrication guidelines, trouble shootings, and necessary information.

For any question about machine operation or maintenance, Nicely team is always ready to assist you!

2026: When Maintenance Becomes Uptime Strategy

The label, flexible packaging, and high-functional converting sectors are entering a period of workforce shortage, automation acceleration, and increasing material complexity.

NICELY is now officially ISO 9001:2015 certified.

On October 21, 2025, we completed our audit and officially received ISO 9001:2015 certification.

Hot-Air Nonwoven Slitting Solutions: Precision Tension Control for Hygiene Materials Manufacturing

When the Chinese leading nonwoven manufacturer required specialized slitting equipment for hot-air nonwoven fabrics, Nicely Machinery recognized this as more than a standard nonwoven slitting system project. Despite our extensive experience with papers, PET films, copper foils, and conventional nonwoven materials, this specific hot-air nonwoven processing presented tension challenges in slitting and rewinding.

Post-Event Insight from Labelexpo Europe 2025: Beyond Price, What Manufacturing Truly Deserves

At the recently concluded Labelexpo Europe 2025, one thing became clear again: the market is highly sensitive to price. When customers approached our booth, the most common question was:

“Why can others offer the same equipment at a lower price?”

Design Driven by Feedback: How Nicely Builds Slitter Rewinders That Truly Work on the Production Floor

In slitter rewinder development, technical features matter. But when the real-world needs of operators are overlooked, even the smartest design can fall flat on the production floor.

NICELY Open House : From Showcase to Co-Creation

On August 15th, 2025, Nicely Machinery welcomed customers, suppliers, trading companies, and peers to our Open House – Technology Day.