2026: When Maintenance Becomes Uptime Strategy

The label, flexible packaging, and high-functional converting sectors are entering a period of workforce shortage, automation acceleration, and increasing material complexity.

Design Driven by Feedback: How Nicely Builds Slitter Rewinders That Truly Work on the Production Floor

In slitter rewinder development, technical features matter. But when the real-world needs of operators are overlooked, even the smartest design can fall flat on the production floor.

Top 3 Practical Retrofits to Increase Converting Line Output

As production demand increases across various markets, many converters are rethinking their equipment strategy. The challenge isn’t always machine age—it’s automation readiness. For many slitter rewinders still running reliably, strategic retrofits can deliver immediate gains in speed, efficiency, and consistency, all without the disruption of a full replacement.

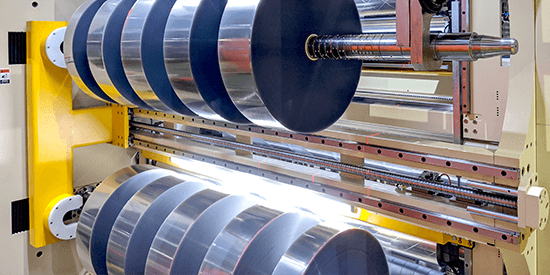

Razor, Shear , Score Cutting? A Basic Guide for Slitting Methods

In the fast-paced world of web converting, choosing the right slitting method can significantly impact your production performance, product quality, and overall operational efficiency.

Slitter Rewinder Machines : A Comprehensive Look at Their Industrial Applications

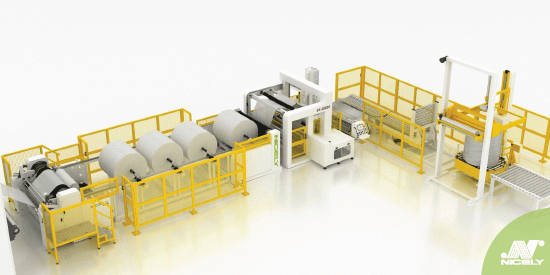

Slitter rewinder machines are indispensable across industries like textiles, packaging, and energy. They transform large rolls into usable formats with precision and consistency, ensuring optimal reel density and size. As industries adopt more automated solutions, slitter rewinders are evolving to meet the demand for high-speed, precise processing while adhering to stringent safety and quality standards.

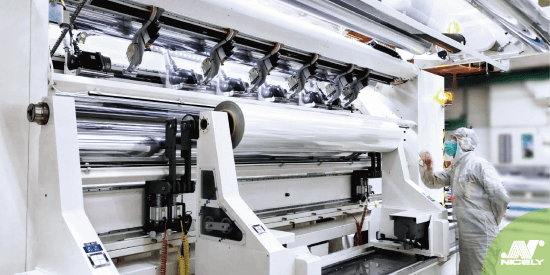

Innovative Film Slitting Technologies for High-Performance Thin Films and Flexible Electronics

The rapid advancement of flexible electronics—such as E-paper, smart packaging, medical sensors, solar cells, automotive components, and touchscreens—is driving significant progress in substrate technologies. High-performance materials such as optical-grade PET and ITO conductive films not only enhance transparency to over 90% but also offer exceptional bendability and durability, achieving material thickness as low as 6 µm to meet the demands for lightweight and high-performance applications.

Stop Downtime - 10 Troubleshooting for Common Slitter Rewinder Machine Problems

Slitter rewinder machines are the unsung heroes behind the scenes for converting materials such as paper, film, foil, electrical insulation, or nonwovens. These machines make stable unwind, precise cuts and consistent rewinds — primary functions that drive production efficiency and ensure product quality. However, despite their vital role, slitter rewinders are often impacted by unexpected downtime, which can disrupt operations, inflate costs, and cause significant operational challenges.

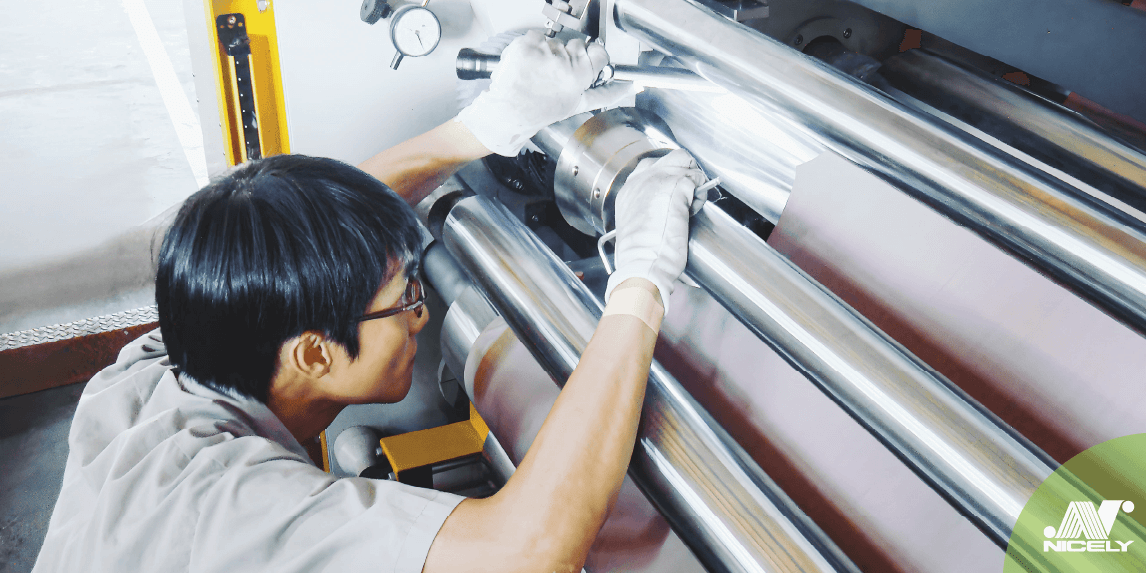

10 Key Maintenance Tasks for Your Slitter Rewinder

Slitter rewinders play a pivotal role in cutting and rewinding materials across various industries, including plastics, paper, film, metal foils, nonwoven textiles, and electrical insulations. Regular maintenance for slitter rewinders is vital not only for ensuring optimal performance but also for extending the lifespan of this critical equipment. This guide outlines 10 key maintenance tasks that owners should prioritize to keep their slitter rewinders operating at peak efficiency.

Film Producer Upgrade Trends: Shifting from New Purchases to Upgrades of Existing Machinery

In recent years, the global film manufacturing industry has faced multiple challenges, including price competition and market saturation. Many companies have had to innovate with high-value-added film products to maintain resilience and avoid falling into the trap of price wars. The film industry covers a wide range of products, from plastic films used in packaging to advanced functional films used in display technologies. Optical films have gained significant attention for their superior optical performance, being widely applied in high-end displays and smartphones with better profit.

Upgrade Your Nonwoven Production with Advanced Slitting Machines

Are nonwoven fabric manufacturers struggling to keep up with the demands of a rapidly changing market? Challenges such as meeting quality standards, maximizing production output, and adapting to new materials are common.

Manual vs. Automated Slitter Rewinder Machine : Pros, Cons, and Modern Trends

In the world of manufacturing and material processing, slitter rewinders play a critical role in converting large rolls of materials into smaller, usable rolls. This article will compare manual and automated slitter rewinder machines, exploring their respective advantages and disadvantages, current industry trends, and scenarios where manual machines may outperform their automated counterparts to help the machine user make decisions confidently.

Nicely : Supporting Your Sustainability Goals with Reliable Paper Slitter Rewinders

The landscape of the paper packaging and paper roll converting industry is undergoing a significant transformation, driven by the increasing demand for sustainable solutions towards paper materials that are biodegradable, recyclable, and reusable. This surge in demand marks a clear shift towards sustainability.

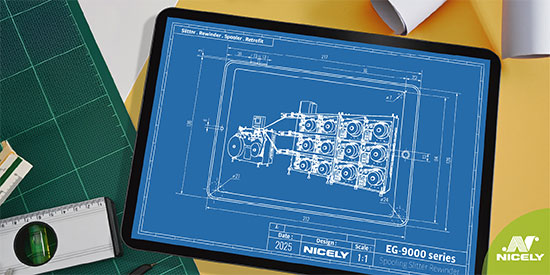

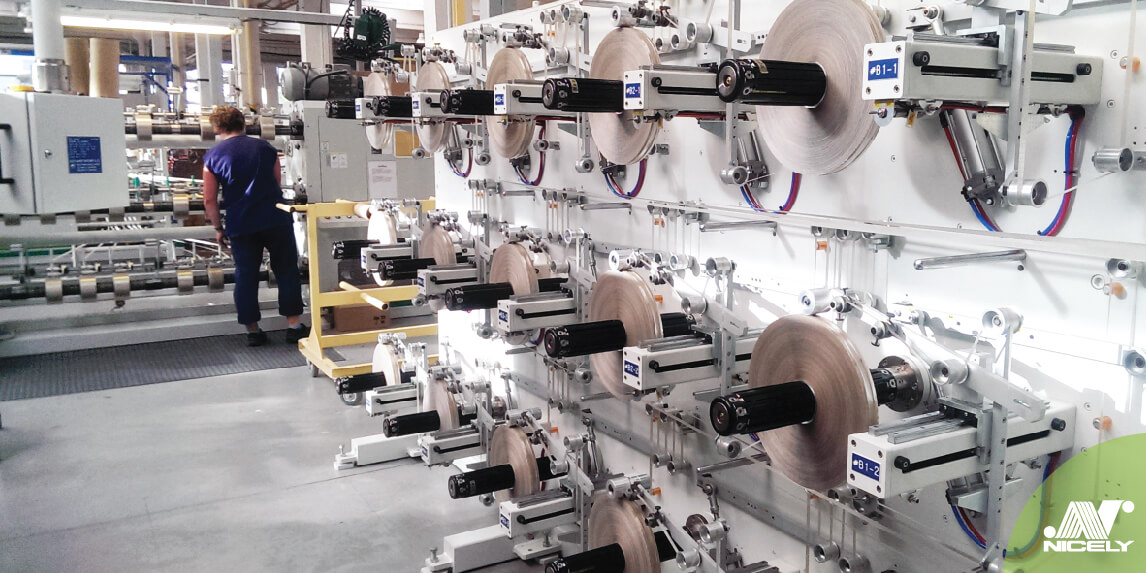

Boost Efficiency with Narrow-Slit Spooling Technology : EG-9000 series Spool Slitter Rewinder

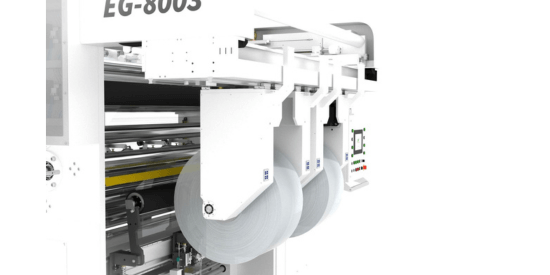

In the equipment manufacturing sector, numerous slitter rewinder manufacturers play significant roles by offering cutting-edge solutions for various materials like paper, film, metal foil, and nonwoven fabric. As slitting technology advances, slitter rewinder specifications push the boundaries.

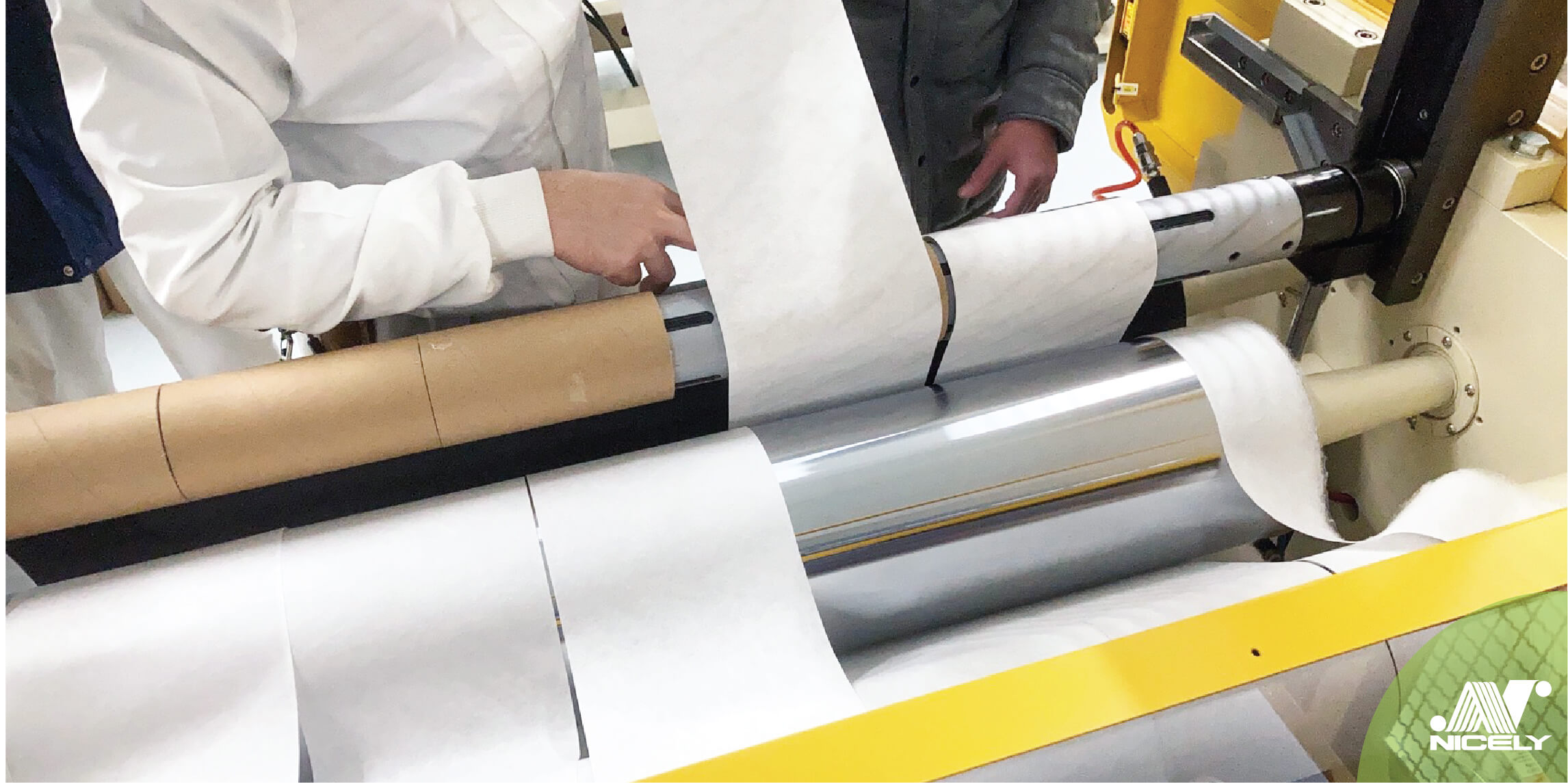

Flexible Packaging Film Slitting : Understanding Slitting Process and Select the Right Slitter

Flexible packaging is fundamental in providing protection and enhancing the visual appeal of consumer products. Central to the operations of this industry is the slitting process for flexible plastic films—which is a mechanism that significantly influences the efficiency and quality of the output.Integrated Solution

E+L Conducted a Comprehensive Product Introduction Session at Nicely

In November, Nicely had the privilege of hosting Jeff Lin, a senior Business Manager from E+L (Erhardt+Leimer ) Taiwan, to conduct a comprehensive product introduction session for our sales and R&D teams. This included insights into the technical applications of new products!

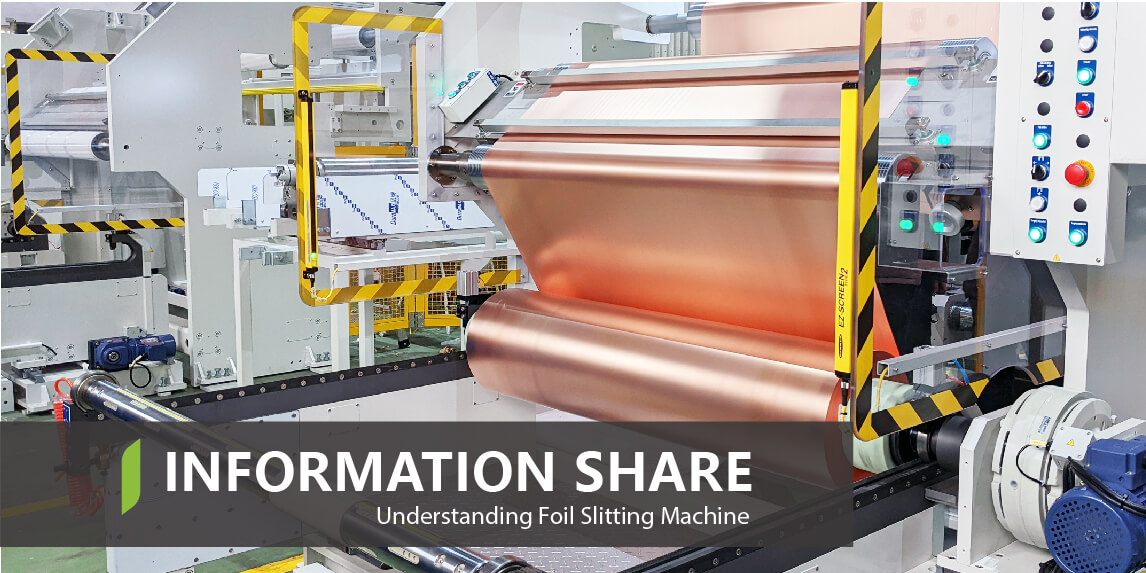

Foil Slitting Machine for Li-Ion Battery and Electro Materials : A Solution to Reduce Waste and Improve Efficiency

A foil slitting machine is a specialized slitter rewinder designed to efficiently cut large rolls of metal foil, such as copper foil and aluminum foil, into the desired width for various applications.

Slitting and Rewinding Machine Investment : Choosing Between New or Retrofit

Investing in a slitting and rewinding machine can be done in two ways : buying a new machine or retrofitting an existing one. Each option has its own pros and cons.

5 Basic Guides of Slitter Rewinders (Part 2)

Let's continue with the second part of our blog series on "5 Basic Guides of Slitter Rewinders." In Part 1, we delved into the fundamental aspects of slitter rewinders, providing you with essential knowledge to kickstart your journey in this industry. Now, in Part 2, we will take you even deeper into the world of slitter rewinders, unveiling more insights and valuable tips.

5 Basic Guides of Slitter Rewinder Machine (Part 1)

Do you know that the slitter rewinder is an essential machine in the converting industry? Its strategic design facilitates the efficient slitting and rewinding of large rolls of material, enabling their transformation into smaller and more specific sizes rolls. These machines assume a key role in various sectors such as packaging, printing, converting, and material processing. The purpose of this guide is to provide you with a thorough understanding of slitter rewinders, empowering you to make informed decisions when it comes to investing in or operating them.

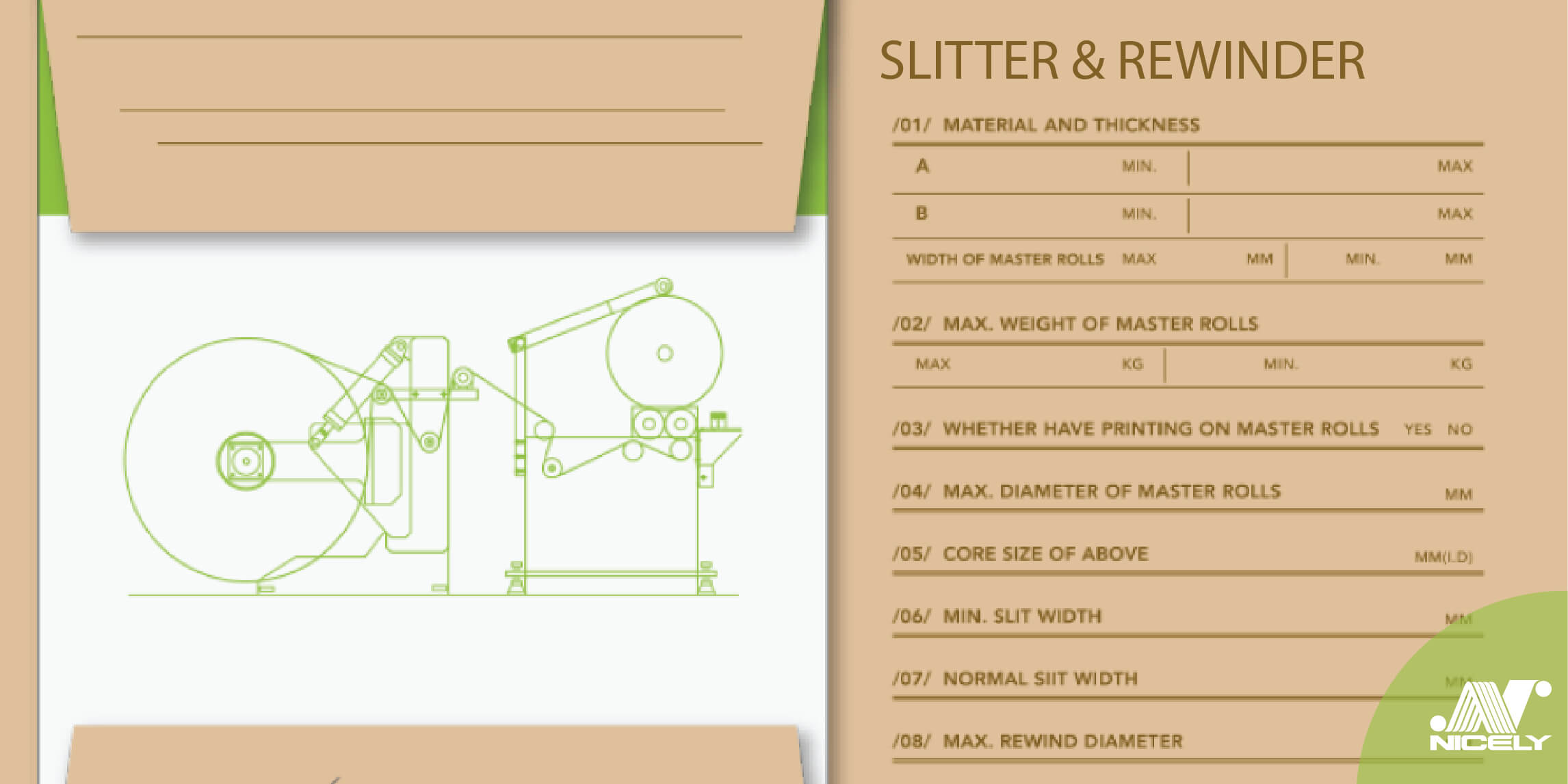

Choosing the Right Slitter Rewinder

Are you in search of the ideal slitter rewinder to effectively slit and rewind your materials? Slitter rewinders play a crucial role in converting large rolls into various sizes, aligning with market demands. Selecting the right machine can significantly enhance your production process. This informative article provides you with comprehensive insights to help you make an informed decision when choosing a slitter rewinder. Keep reading to learn the key factors to consider and the essential information to communicate with the manufacturer before requesting a quote.

Maintenance and Troubleshooting Tips for Slitter Rewinder Owners

Establish a Regular Maintenance Schedule, Keep the Machine Clean and Lubricated, Check the Tension and Alignment of the Web, Monitor the Blade Sharpness and Wear, and Diagnose and Troubleshoot Issues Promptly.