Manual vs. Automated Slitter Rewinder Machine : Pros, Cons, and Modern Trends

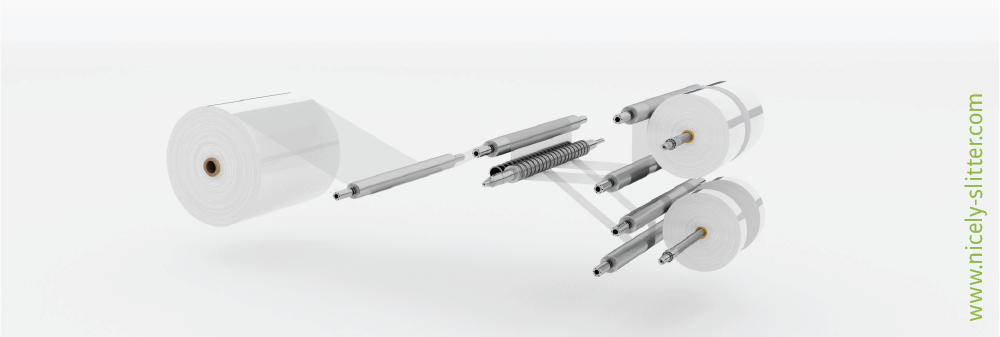

Customer Care 2024-06-26In the world of manufacturing and material processing, slitter rewinders play a critical role in converting large rolls of materials into smaller, usable rolls. This article will compare manual and automated slitter rewinder machines, exploring their respective advantages and disadvantages, current industry trends, and scenarios where manual machines may outperform their automated counterparts to help the machine user make decisions confidently.

Evolution of Slitter Rewinders

Slitter rewinders have come a long way since their inception. Initially developed to meet the growing demand for efficient material handling in industrial settings, early models were entirely manual and relied heavily on the skill of the operator. Over time, technological advancements introduced motorized components, improving the speed and precision of the slitting process. The integration of computer controls and automation in recent decades has revolutionized these machines, making them indispensable in industries such as packaging, printing, textiles, and even electronics high-tech and energy applications. Today’s slitter rewinders are sophisticated systems capable of high-speed operation, precision cutting, and minimal waste, reflecting the continuous innovation in this field.

Manual Slitter Rewinders

Manual slitter rewinders operate through direct human intervention, where operators handle the slitting and rewinding processes.

The EG-2L Duplex Shaft Surface Winding Slitter : A rather manual model with great capability of handling large paper rolls.

The EG-2L Duplex Shaft Surface Winding Slitter : A rather manual model with great capability of handling large paper rolls.

Pros:

- Lower Initial Investment:Manual slitter rewinders typically have a lower upfront cost compared to their automatic counterparts. This makes them a more affordable option for small businesses or startups with limited capital.

- Simplicity and Ease of Use:Manual slitter rewinders are often simpler in design and operation, making them easier to understand and operate. They require minimal training for operators and can be quickly integrated into existing production workflows.

- Low Maintenance and Repairs:With fewer complex components and automation features, manual slitter rewinders are generally easier and less expensive to maintain and repair. Routine maintenance tasks can be performed in-house without the need for specialized technicians.

Cons:

- Labor-Intensive Operation:Manual slitter rewinders require constant manual operation and oversight by operators. This can be labor-intensive and may result in inefficient productivity.

- Inconsistent Output:The manual nature of operation increases the risk of human error, leading to variations in product quality and consistency.

- Limited Efficiency and Workflow Optimization:Manual slitter rewinders lack the advanced automation features found in automatic machines, such as automatic tension control and knife arrangement. This can result in less efficient material handling and workflow optimization, leading to potential production delays.

- Dependency on Operator Skill:The performance and output quality of manual slitter rewinders heavily depend on the skill and experience of the operator, leading to the challenge of sufficient operating knowledge.

Automated Slitter Rewinders

Automated slitter rewinders use advanced technology to perform cutting and rewinding with minimal human intervention.

The EG-7009 Duplex Shaft Center Winding Slitter Rewinder : A highly popular model featuring multiple integrated automations, including auto. knife system, auto laser positioning, roll handling, conveying, and packing…etc in the converting process.

The EG-7009 Duplex Shaft Center Winding Slitter Rewinder : A highly popular model featuring multiple integrated automations, including auto. knife system, auto laser positioning, roll handling, conveying, and packing…etc in the converting process.

Pros:

- Precision and Consistency:Automation in slitting and rewinding processes ensures precise and consistent results. This consistency not only enhances product quality but also reduces waste and rework, ultimately leading to cost savings and improved customer satisfaction.

- Quick Changeover and Setup:Contrary to the belief that automatic machines are only suitable for large production runs, many modern automatic slitter rewinders are designed for quick changeovers and easy setup.

- Increased Productivity and Efficiency:By automating repetitive tasks and minimizing manual intervention, automatic slitter rewinders significantly increase productivity and operational efficiency. Operators can focus on supervising and optimizing production processes rather than performing labor-intensive tasks, leading to higher throughput and reduced lead times.

Cons:

- Higher Initial Investment:Automatic slitter rewinders typically come with a higher upfront cost compared to manual machines.

- Complex Maintenance and Repairs:The sophisticated automation systems in some ways require specialized knowledge for maintenance and repairs. In the event of a breakdown or malfunction, troubleshooting and fixing issues may require skilled technicians or manufacturer support.

- Dependency on Technology:Automatic slitter rewinders heavily rely on technology and electrical components to function. Any disruptions in power supply, software glitches, or mechanical failures can halt production and result in significant downtime until the issues are resolved.

- Training and Adaptation:Transitioning from manual to automatic slitter rewinders may require additional training for operators to familiarize themselves with the new technology and operation procedures.

While automatic slitter rewinders offer numerous benefits, it's essential for businesses to carefully weigh their specific production needs, budget constraints, and long-term goals before making a purchasing decision.

| Criteria |

With More Manual Functions |

With More Automated Functions |

|---|---|---|

Initial Investment |

.png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Lower initial cost |

Higher initial cost |

Ease of Use & Training |

.png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Simple operation, minimal training |

Requires training for both operational the electrical skills |

Maintenance and Repairs |

.png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Minimal and inexpensive maintenance |

Complex maintenance, require skilled technicians |

Labor Intensity |

Labor-intensive operation |

.png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Reduced labor requirement |

Output Consistency |

Prone to human error, inconsistent output |

.png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Precise and consistent output |

Efficiency and Workflow |

Limited automation, potential inefficiencies |

.png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Streamlined processes, increased efficiency |

Operator Dependency |

Relies on operator skill | .png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Dependent on technology, reduced reliance on operator skill |

Changeover and Setup |

Manual adjustment, longer setup times, and frequent downtime |

.png?c7586couz3?r06rk3xnd0?elfx067wyp?otjl1h76j0?l9uqkrbhwa?k0ak0y80iu?yyjjejtwfn?nm1rluaza3) Quick changeover, efficient setup, and preventive maintenance reminder |

When Manual Slitting Machines Are Better?

Despite the advantages of automation, there are situations where manual slitter rewinders are preferable.

-

Low Volume, High Variety Jobs:

Manual machines offer the flexibility to switch between different tasks quickly and efficiently.

-

Budget Constraints:

Lower initial costs are beneficial for small businesses or those with limited capital.

-

Simplicity and Control:

Easier to operate and manage without needing extensive technical training.

Automation Trends in Slitter Rewinders

Modern trends in slitter rewinder technology focus on efficiency, sustainability, and digital integration. Here are the main focus from the market review.

-

Automation and AI:

Increasing use of AI for predictive maintenance and optimizing the slitting process.

-

Sustainability:

Development of energy-efficient models and methods to reduce material waste.

-

Customization and Modularity:

Machines are being designed to be easily customized and scaled according to specific needs.

-

Digital Integration:

Incorporation of IoT technology for real-time monitoring, data analysis, and improved operational efficiency.

Choosing the Right Slitter Rewinder

Choosing between manual and automated slitter rewinders depends on your needs, production volume, and budget. Automated machines offer high efficiency and quality, while manual machines are cost-effective and low maintenance. or struggling with the decision to acquire a new machine or retrofit an existing one? Each option has its pros and cons.

Unsure? Contact Nicely Machinery's Slitter Rewinder Retrofitting Experts for a free consultation.

For detailed information, explore our guide, "5 Basic Guides of Slitter Rewinders," covering types, components, applications, maintenance, and purchasing tips.