What is a Slitter Rewinder?

A slitter rewinder is a specialized machine to perform three primary functions:

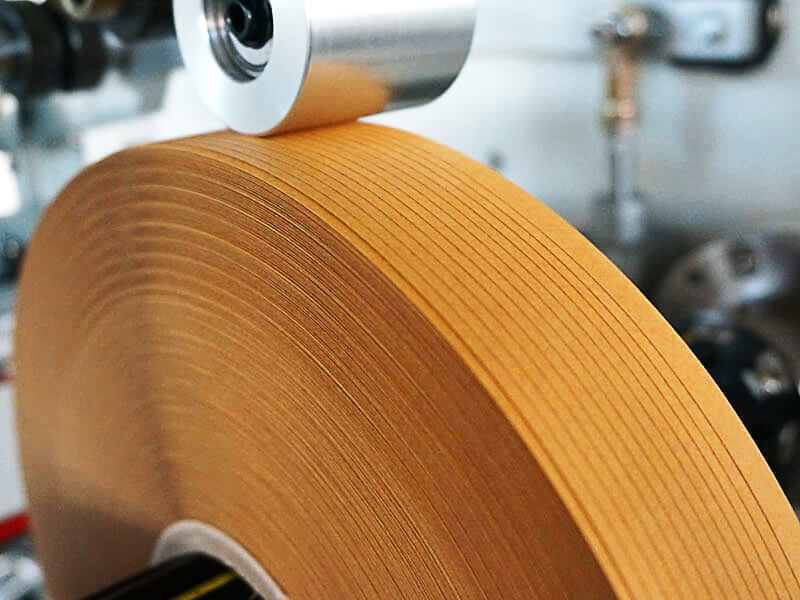

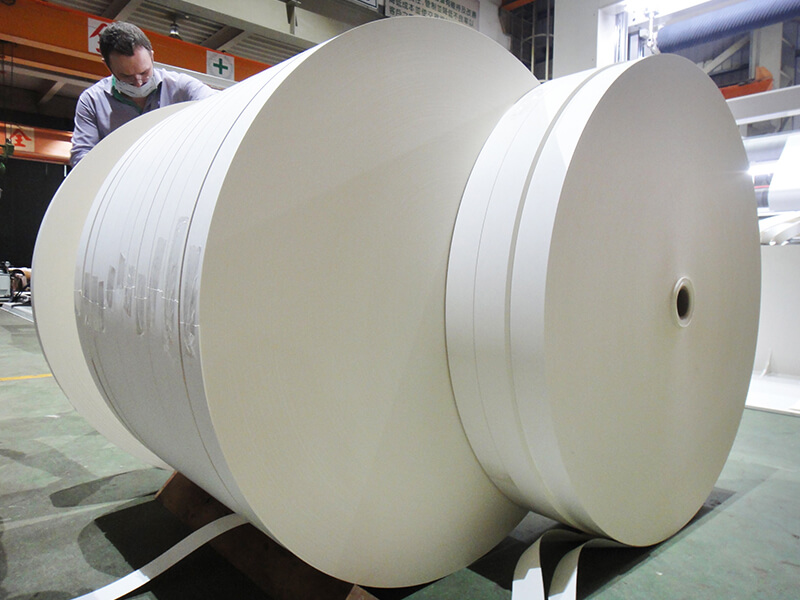

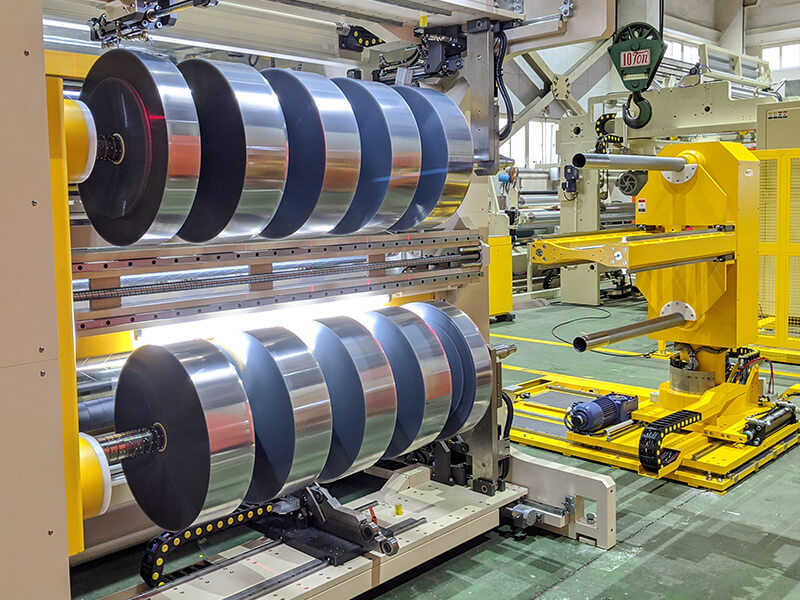

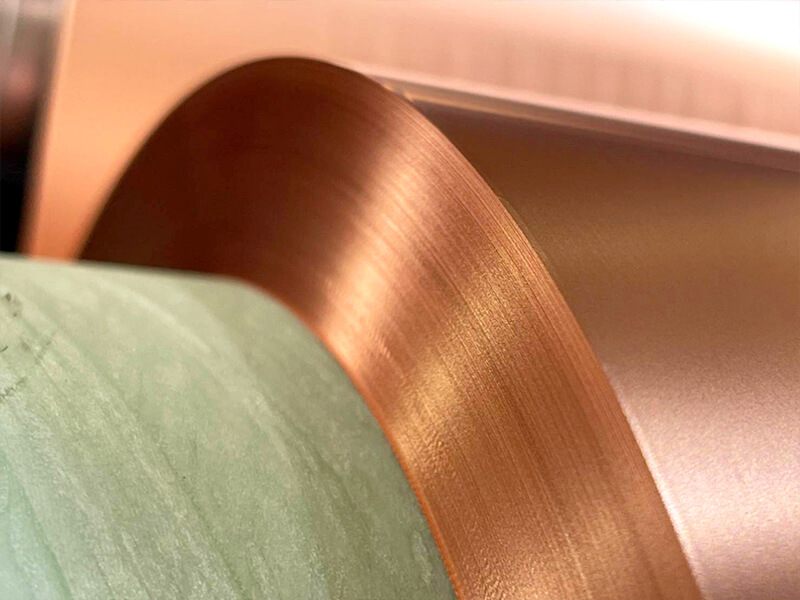

unwinding, slitting and winding. It is widely used in the converting industry for cutting large jumbo rolls of materials, such as paper, film, foil, electrical insulation, or nonwovens into narrower rolls while simultaneously rewinding them into finished reels.

This process is essential for preparing materials for subsequent production stages or final applications in flexible packaging, energy storage, hygiene products, and high-performance electronics.

How Does a Slitter Rewinder Work?

A slitter rewinder works by unwinding large jumbo rolls, cutting them into narrower widths using precision slitting methods such as razor blades, shear knives, or score slitting systems as it follows the designate web path and then rewinding the cut strips into finished reels. This process requires precise control of material tension, accurate slitting techniques and operator-friendly unloading adaptation to achieve clean cuts, consistent roll density and smooth production cycle, making it an essential step for quality and production output assurance.

Modern slitter rewinders often feature advanced automation, integrated data management systems, and ergonomic unloading functions to boost operational efficiency and product consistency. These enhancements solidify their role as indispensable tools for industries striving to meet evolving market demands and maintain a competitive edge.