Choosing the Right Slitter Rewinder

Customer Care 2023-05-16Choosing the Right Slitter Rewinder: A Comprehensive Guide to Meet Your Production Needs –

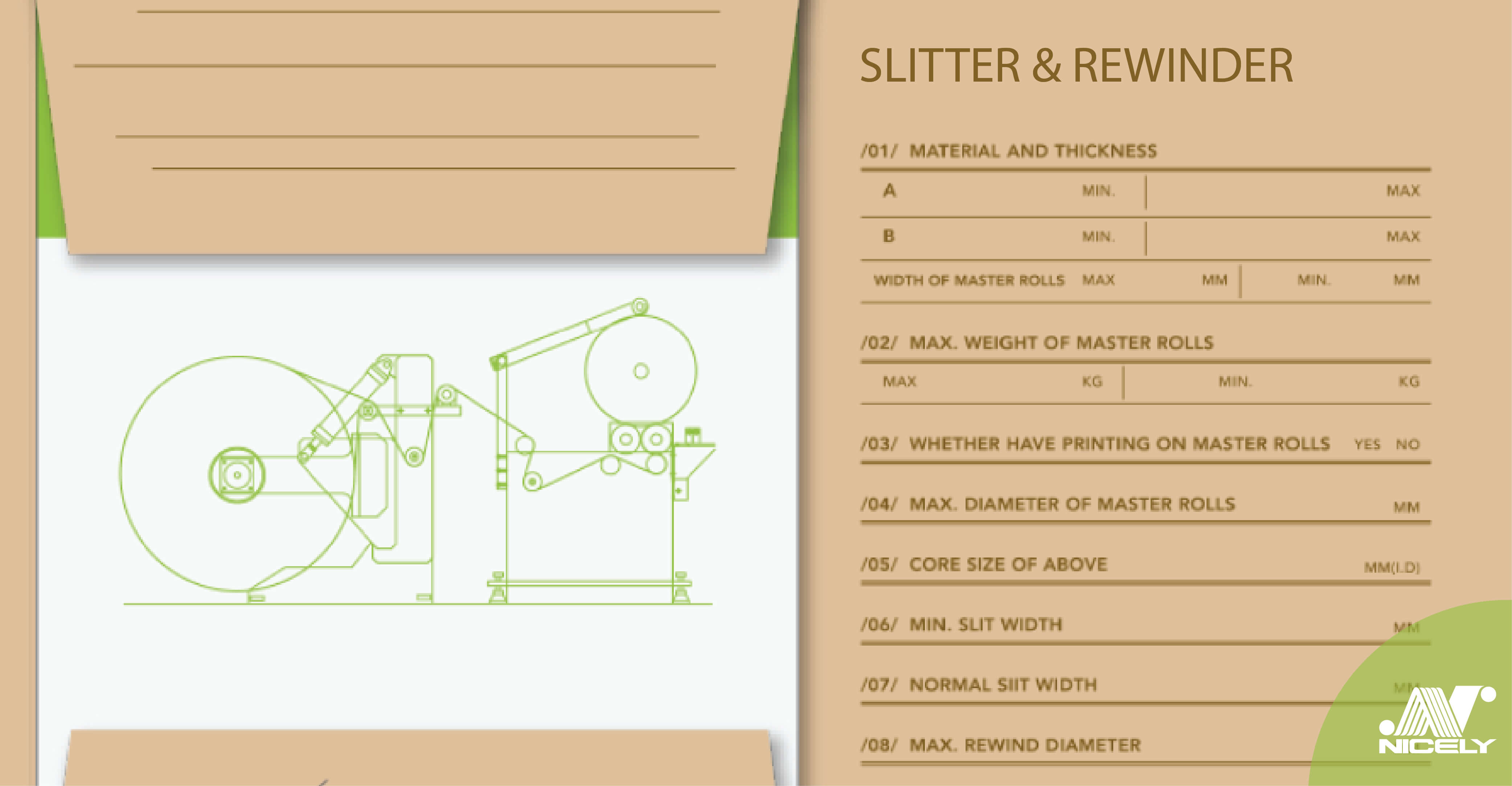

Are you in search of the ideal slitter rewinder to effectively slit and rewind your materials? Slitter rewinders play a crucial role in converting large rolls into various sizes, aligning with market demands. Selecting the right machine can significantly enhance your production process. This informative article provides you with comprehensive insights to help you make an informed decision when choosing a slitter rewinder. Keep reading to learn the key factors to consider and the essential information to communicate with the manufacturer before requesting a quote.

Understand Your Material Before diving into the selection process, it's essential to have a clear understanding of the material you will be processing. Different slitter rewinders are specifically designed to handle various materials, such as paper, film, or foil. Consider important factors like material thickness, strength, and roll diameter to ensure the chosen slitter rewinder aligns perfectly with your material requirements.

Identify Your Required Specifications Precisely identifying the specifications you need for your slitter rewinder is crucial. Determine the desired width and length of the finished rolls, the number of cuts required, and the desired machine speed. These specifications will play a significant role in determining the most suitable type of slitter rewinder to meet your production needs effectively.

Equipment Capacity Calculation Accurate calculation of the equipment capacity based on projected output is paramount in selecting the perfect slitting machine for your production needs. Engage in detailed discussions with manufacturers, exploring various specifications, functionalities, and compatible solutions. Consider options such as increasing machine speed, enhancing automation levels, and minimizing manual intervention in operational processes. By precisely determining your capacity requirements, you can establish an efficient slitter rewinder that ensures a favorable return on investment. This strategic planning also minimizes the potential for future equipment replacement or upgrade needs, leading to substantial cost and time savings for your business.

Choose a Reliable Manufacturer Selecting a reputable and reliable manufacturer is of utmost importance when investing in a slitter rewinder. Look for manufacturers with a proven track record, extensive industry experience, and positive customer reviews. Additionally, inquire about their after-sales support and warranty policies to ensure you receive the necessary assistance and service throughout the equipment's lifespan.

Provide Accurate Information to the Manufacturer When reaching out to a slitter rewinder manufacturer, ensure you provide accurate and detailed information about your material, specifications, and production needs. This enables the manufacturer to recommend the most suitable slitter rewinder for your unique requirements. Don't forget to inquire about customization options that may be available to tailor the machine to your specific needs. Selecting the right slitter rewinder is vital for optimizing your material processing and meeting your production needs. By understanding your material, identifying specifications, calculating equipment capacity, and choosing a reliable manufacturer, you can make an informed decision that ensures seamless operations, cost savings, and maximum efficiency for your business.

We hope this information was helpful, and should you need further technical support, please don't hesitate to contact Nicely's team at [email protected] or fill out the service form on https://nicely-slitter.com/en/contact.html