Duplex Center Winding Slitter Rewinder

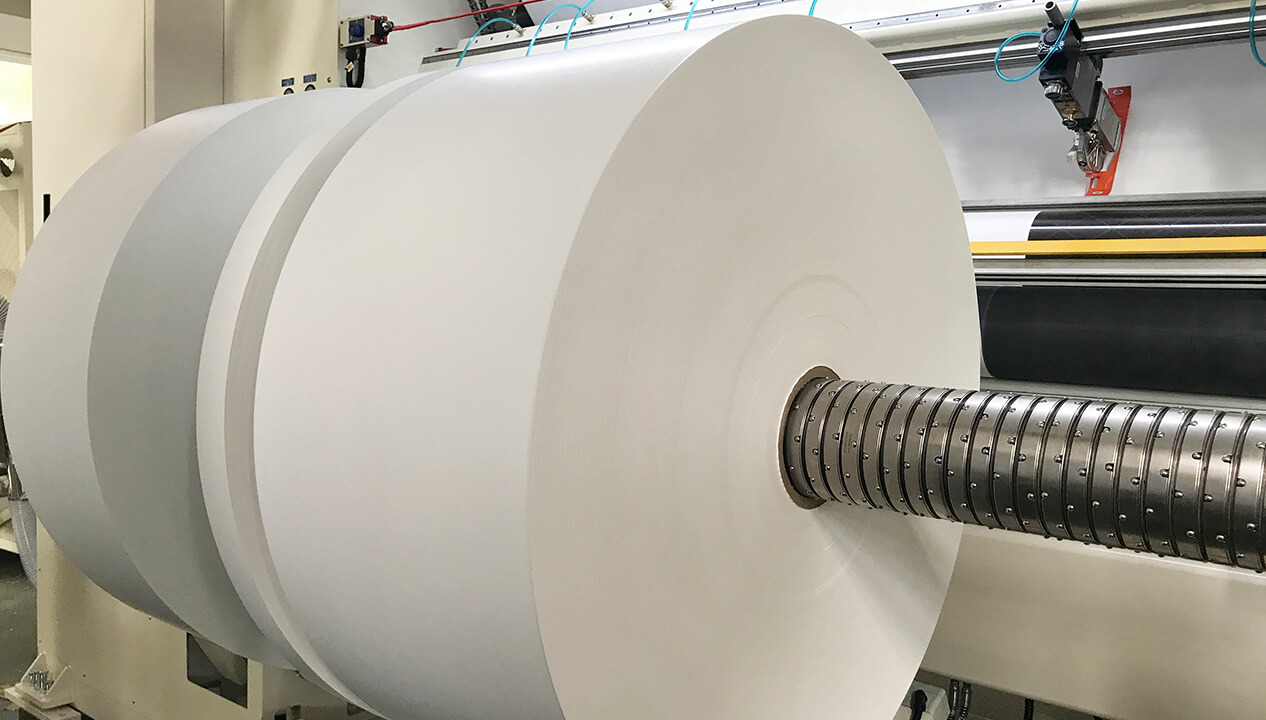

• Coated, uncoated paper, cardboard

• Tissue paper

• Filter paper

• LLDPE / Nonwoven / Laminations

• PSA , film & paper labelstock

• Liner-less thermal papers

• Pharmaceutical materials

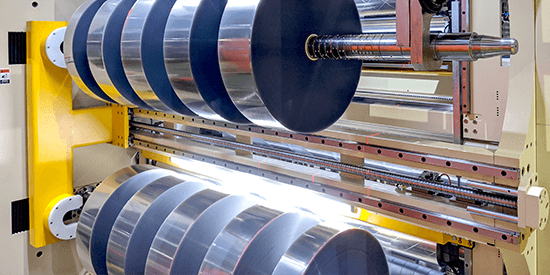

• Aluminum lamination

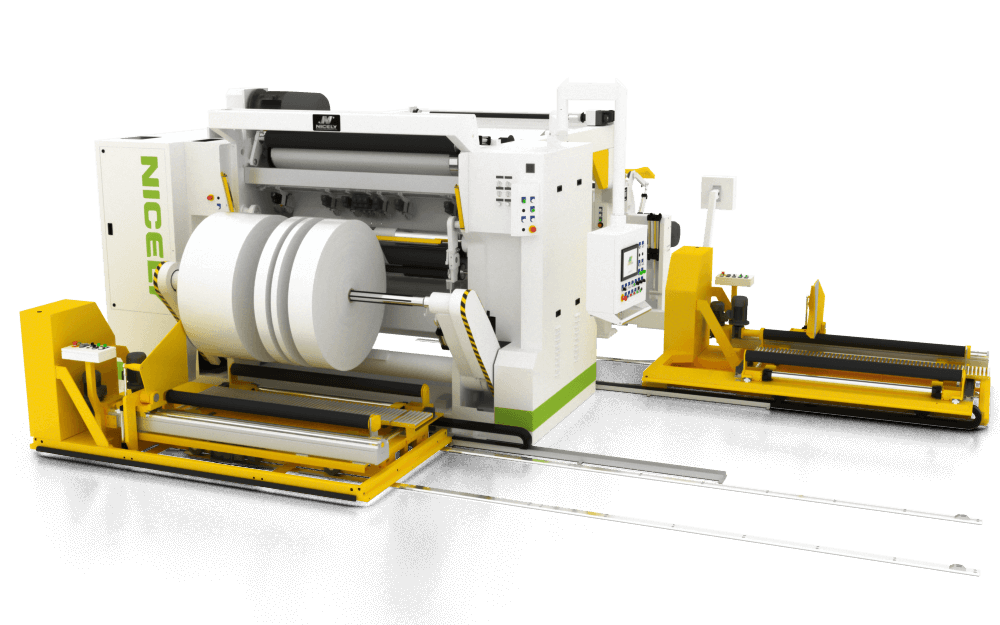

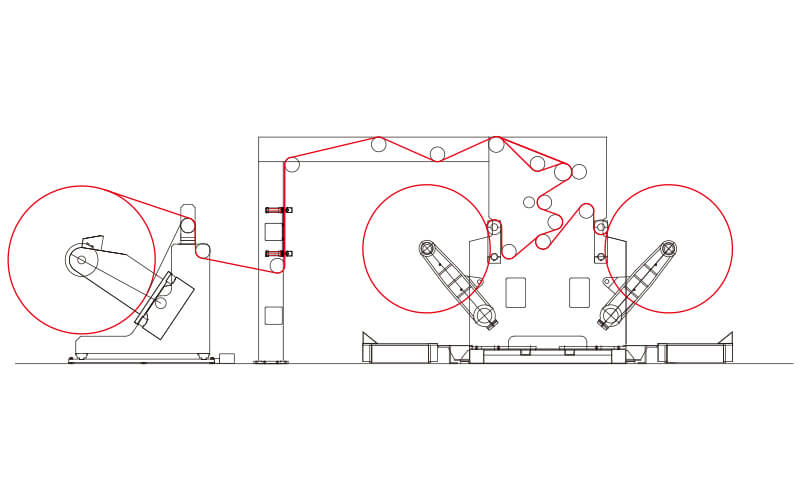

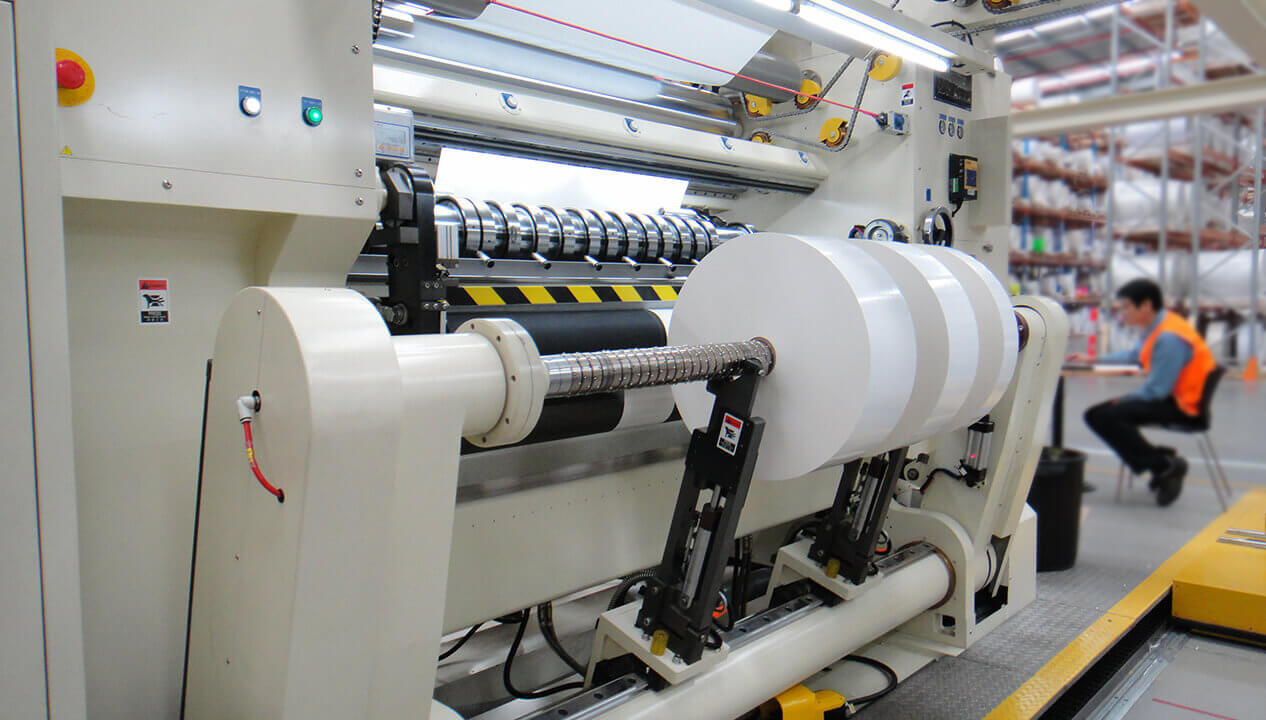

EG-8002, the upgraded version of the EG-300 series machine, combines the benefits of its center-surface design while expanding its specifications to accommodate rewind diameters of up to 1200mm. EG-8002 offers enhanced capabilities for larger-scale operations. Notably, this machine features winding shafts that load directly onto motorized unloading carts. As the carts move away, the finished reels are effortlessly extracted from the shafts, streamlining the unloading process. This innovative design promotes efficiency and convenience, allowing for seamless handling of finished reels

Standard Features

- Shaftless unwind stand.

- Shear or razor cutters.

- Trim removal system.

- Spreader roller.

- Manual unloading trolley.

- PLC control system incorporate with HMI touch screen.

- Splice device.

- Inspection lightbox.

- Motorized web threading.

- Pneumatic cutters.

- Auto. knife positioning.

- Differential rewind shaft.

- Dust remover.

- Motorized unloading trolley.

- Trim waste winder.

- Enhanced fencing & safety implements.

| Roller width | 1200 – 2600 mm |

|---|---|

| Unwind diameter | 1200 mm and up |

| Min. slit width | 50 mm and up |

| Rewind diameter | 1200 / 1500 mm |

| Machine speed | 400 / 600 / 800 M/min |

* Other specifications are offered at request.

The landscape of the paper packaging and paper roll converting industry is undergoing a significant transformation, driven by the increasing demand for sustainable solutions towards paper materials that are biodegradable, recyclable, and reusable. This surge in demand marks a clear shift towards sustainability.

Following the intensive acceptance schedule with our European client at the end of March, which involved three days of rigorous testing and review, Nicely has completed some significant add-ons in April. This included the shipment of two EG-7009 duplex shaft slitter rewinders and one EG-R900 doctoring machine with a trim winder, all designed for pharmaceutical packaging.

Flexible packaging is fundamental in providing protection and enhancing the visual appeal of consumer products. Central to the operations of this industry is the slitting process for flexible plastic films—which is a mechanism that significantly influences the efficiency and quality of the output.Integrated Solution

In November, Nicely delivered an EG-8002 Duplex Shaft Center Winding Slitter Rewinder, designed for slitting PE-coated paper and food packaging applications. This marks the fourth equipment supplied to our client, a leading supplier in Taiwan's food paper packaging sector.

Nicely Machinery provides retrofitting and upgrading services for customers who have older slitter rewinders, whether machines were originally from Nicely or another supplier.