Upgrade & Retrofit

The upgrading implementation includes :

• Rewind arms replacement

• Automated functions for rewind arms

• Automated knife positioning

• Drives replacements

• PLC control systems upgrade

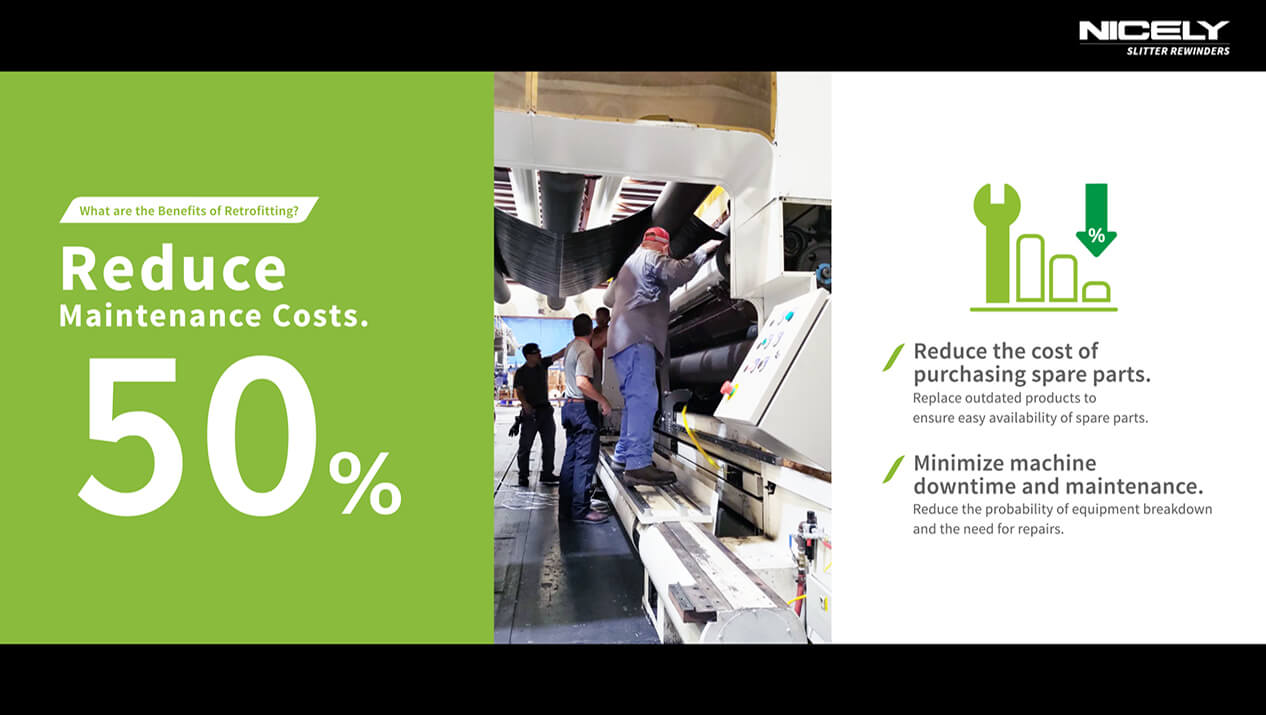

When equipment's production efficiency is limited, and maintenance frequency is high, or the level of automation is outdated, it directly impacts costs.

In addition to offering brand-new slitter rewinders, Nicely understands that sustainability is one of the crucial directions for today's businesses. To meet these needs, Nicely provides recommendations for refurbishing and retrofitting existing equipment, which can align with the planning of the front and back-end production lines, enabling greater automation and significantly reducing labor and resource consumption.

By modifying machine structures, material processes, and upgrading control systems, we can extend the lifespan of older machines and enhance their production efficiency. We are confident in helping customers save up to 50% of their investment budgets and substantial maintenance costs while assisting businesses in implementing environmental sustainability principles.

Email : [email protected]

Maximizing Your Slitter's Potential: Upgrade Instead of Replace

Is your slitter rewinder falling behind industry standards?

Nicely Machinery offers retrofitting and upgrading services for older machines, whether they're from us or another supplier.

Here are the benefits:

| ● Efficiency Boost : | Retrofitting brings your machine up to current standards, enhancing efficiency. |

| ● Cost Savings : | Get the advantages of new technology without the expense of buying a new machine. |

| ● Sustainability : | Extend your equipment's life, reducing waste and environmental impact. |

| ● ROI : | Enjoy a substantial return on your investment. |

| ● Expert Guidance : | Our experienced technical supports ensure a successful retrofitting project. |

For more details and successful cases, contact us :

Email : [email protected]

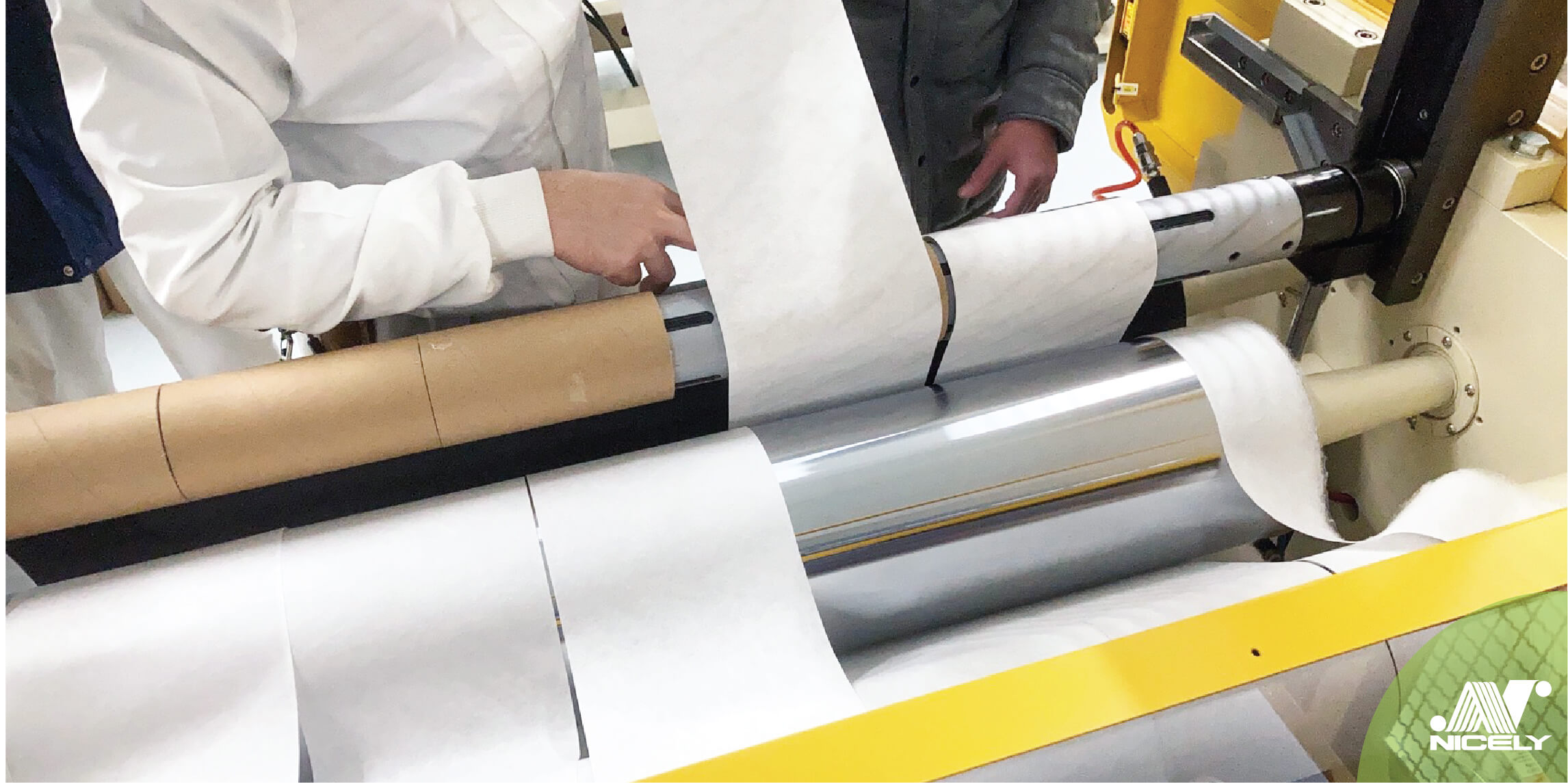

A Taiwanese leading nonwoven manufacturer, has recently completed a significant retrofitting project on their 3600mm nonwoven slitter rewinder, model EG-2001GA. Originally acquired in 2014 for handling nonwovens, this upgraded slitter is now set to meet the demands of their growing overseas market.

Establish a Regular Maintenance Schedule, Keep the Machine Clean and Lubricated, Check the Tension and Alignment of the Web, Monitor the Blade Sharpness and Wear, and Diagnose and Troubleshoot Issues Promptly.

Nicely Machinery provides retrofitting and upgrading services for customers who have older slitter rewinders, whether machines were originally from Nicely or another supplier.