Spooling Slitter Rewinder

• Film lamination

• Glass Fiber lamination

• Press Paper

• Mica tap

• Cover tape

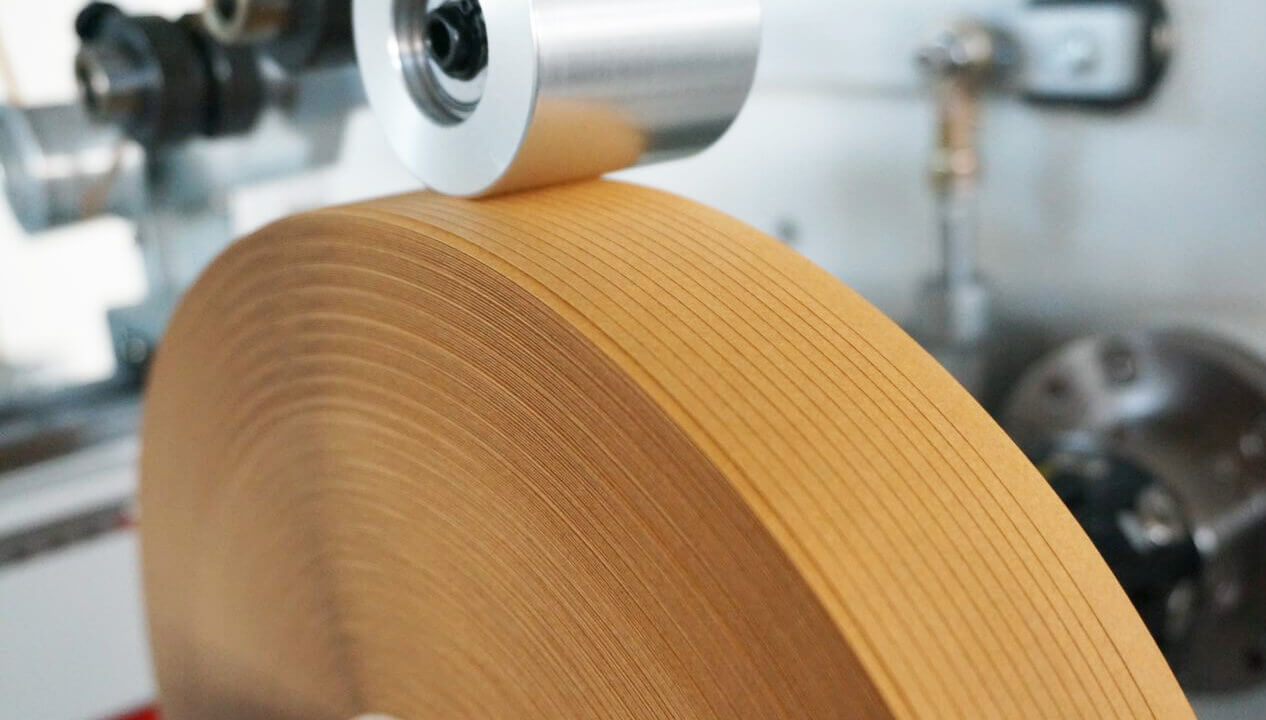

• Insulation Paper

• Carrier Tape

• Masking Tape / Hot Melt Tape

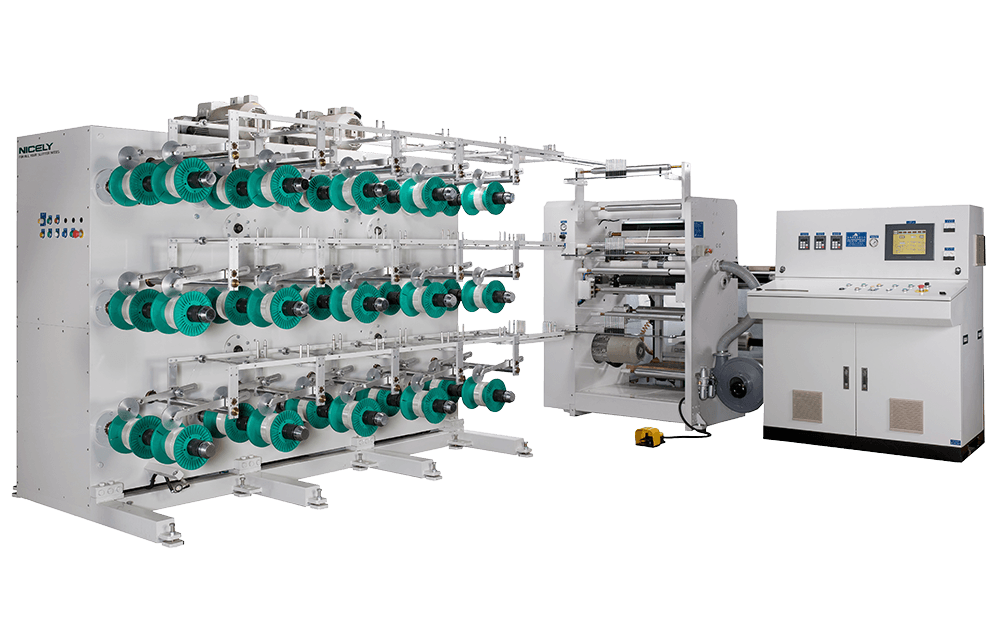

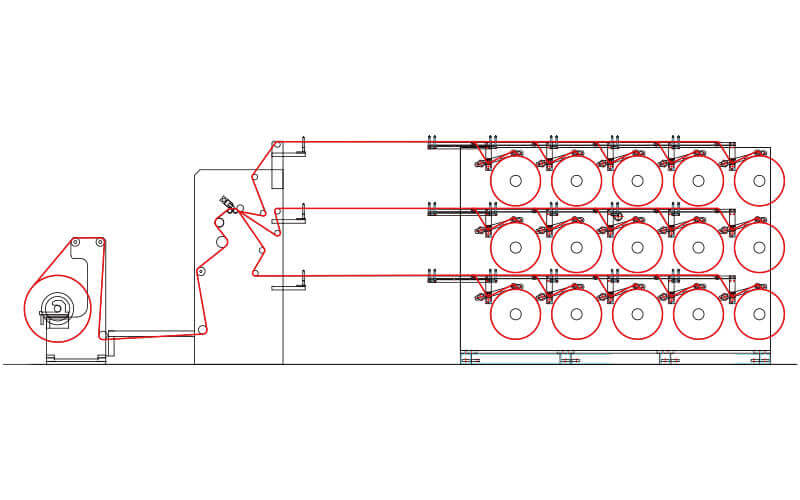

Featuring a minimum slitting width of 2mm and a modular design, it effortlessly expands from a basic set of 6 spools to meet the specific requirements. Additionally, the spooling slitter offers versatile winding patterns, including traverse, taper, stag, and flanged winding, ensuring optimal handling of insulation materials.

Read more about EG-9000 Series:Boost Efficiency with Narrow-Slit Spooling Technology : EG-9000 series Spool Slitter Rewinder

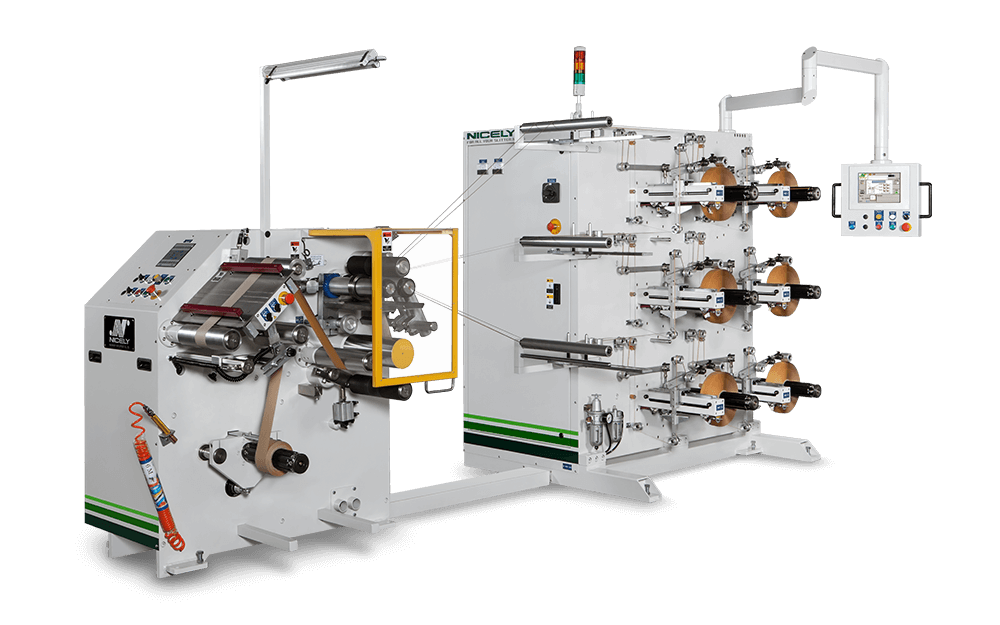

- Shafted unwind stand. Ideal for narrow web spooling applications, the shafted unwind stand offers reliable and stable material feeding for the slitting process.

- Choice of shear or score cutter. With the option to choose between shear and score slitting, customers can select the most suitable cutting method based on their specific requirements and material properties.

- The minimum slitting width is 2mm. The EG-9000 series spooling slitter rewinder provides a minimum slitting width of 2mm, offering precision and accuracy for small width materials.

- Individual trim winder. The individual trim winder helps to keep the work environment clean and tidy by collecting the edge trim waste from the slitting process in a separate spool.

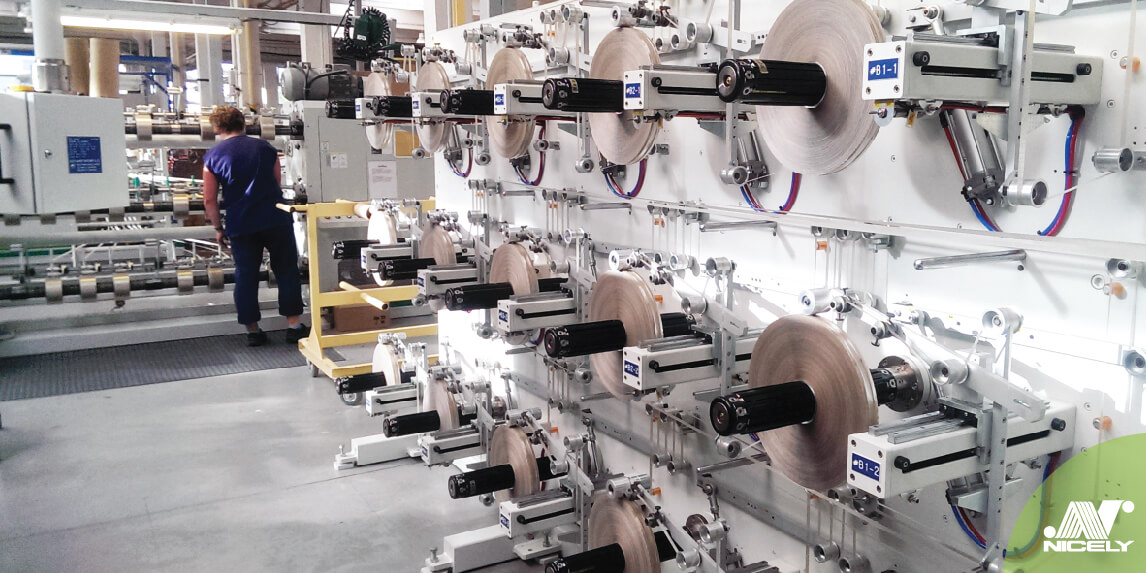

- The spooling option allows for expansion from 6 spools. With the flexibility to expand from a basic set of 6 spools, the EG-9000 series spooling slitter rewinder can meet the growing demands of customers.

- The machine offers flexible winding patterns, such as traverse, taper, stag, and flanged winding. Customers can choose from a range of winding patterns to suit their specific needs, including traverse winding, taper winding, stag winding, and flanged winding.

- PLC with human interface operation. The EG-9000 series spooling slitter rewinder is equipped with a user-friendly PLC with human interface operation, allowing for easy and efficient control of the slitting process.

| Machine roll width | 600 mm |

|---|---|

| Unwind diameter | 600 mm |

| Min. slit width | 2 mm and up |

| Rewind diameter | 450 mm, max. |

| Traverse range | 250mm. |

| Mechanical Speed | 200 M/min |

* Other specifications are offered at request.

_pic.png)

In March, Nicely successfully delivered an EG-3D9220 Spooling Slitter Rewinder to Vietnam.

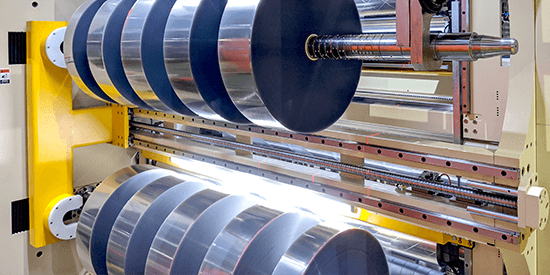

In the equipment manufacturing sector, numerous slitter rewinder manufacturers play significant roles by offering cutting-edge solutions for various materials like paper, film, metal foil, and nonwoven fabric. As slitting technology advances, slitter rewinder specifications push the boundaries.

Flexible packaging is fundamental in providing protection and enhancing the visual appeal of consumer products. Central to the operations of this industry is the slitting process for flexible plastic films—which is a mechanism that significantly influences the efficiency and quality of the output.Integrated Solution