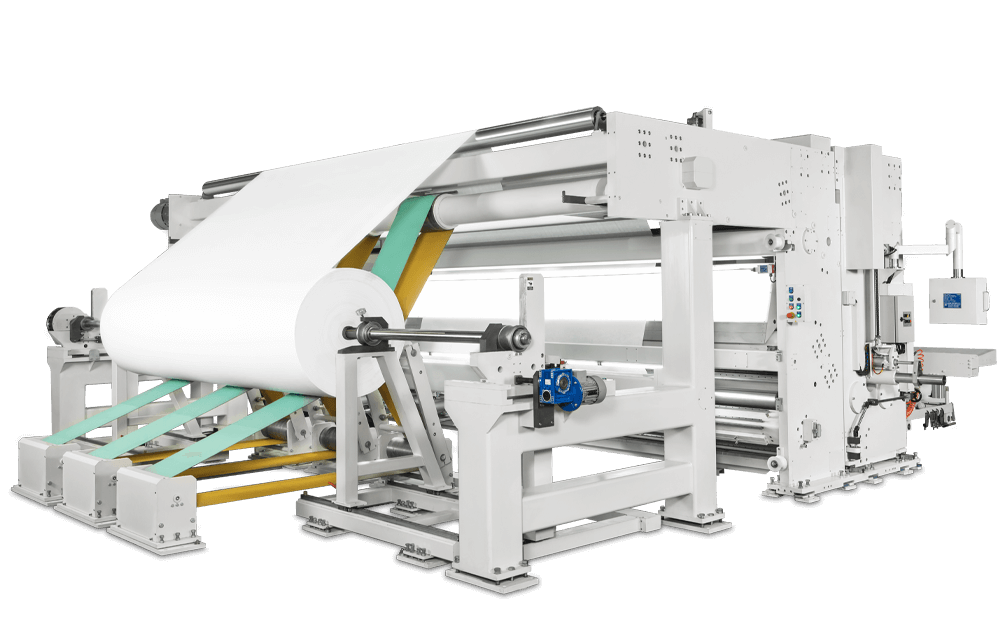

Nonwoven Slitter Rewinder

• Meltblown nonwovens

• Airlaid nonwovens

• Spunlace nonwovens

• Spunbond nonwovens

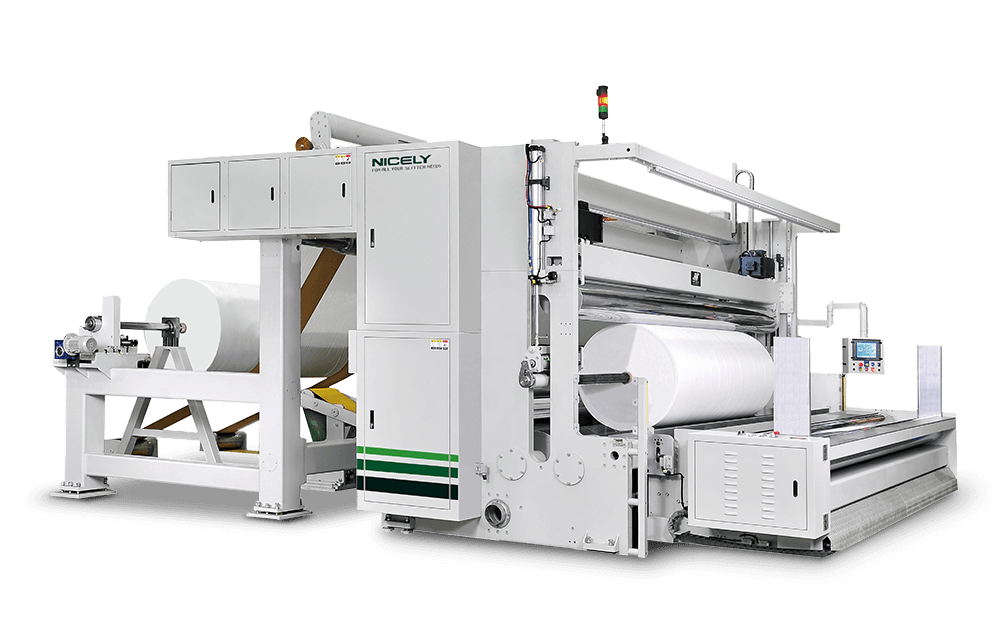

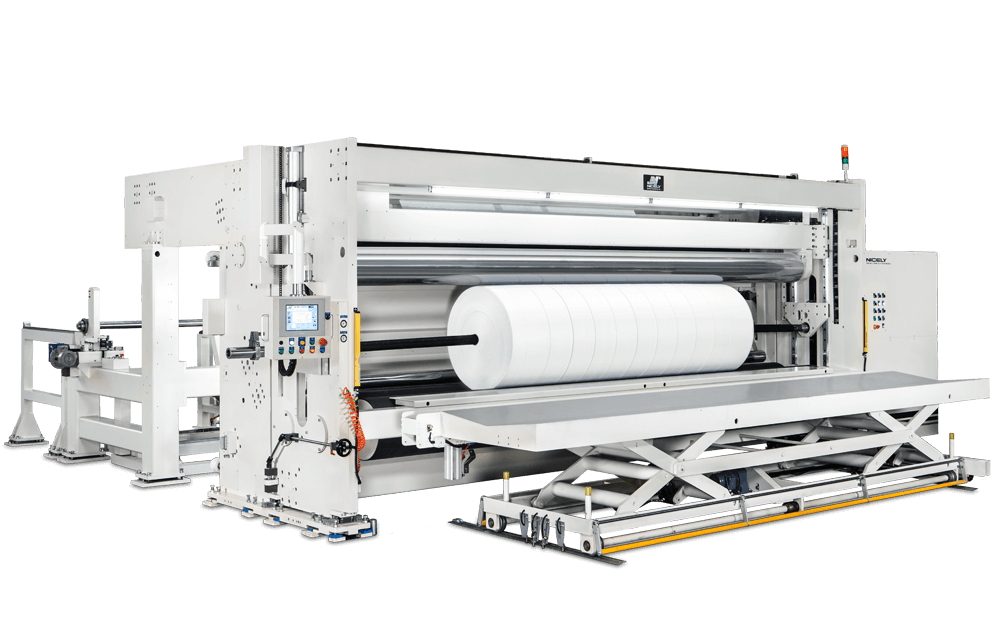

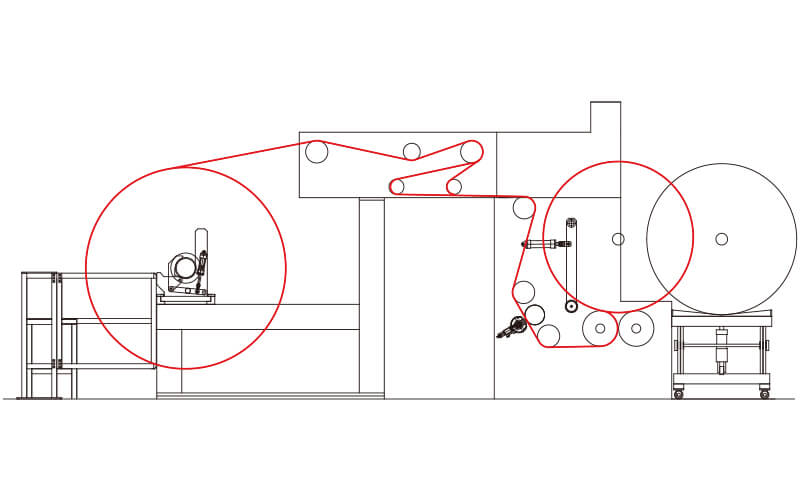

EG-2001G series is specifically designed as a Non Woven Slitting Machine, offering several notable features. One of these features is the auxiliary belt-assisted unwinding, which enables precise control of material tension, effectively preventing overstretching and ensuring stability during transportation. The tension control system, integrated with a dancer roll, automatically adjusts to accommodate variations in material thickness. Moreover, the EG-2001G Non Woven Slitting Machine can be complemented with various automation options, such as auto knife setting, shaft handling, and unloading, to significantly enhance productivity. Additionally, the system allows for seamless integration of finished roll handling and packaging systems, providing a comprehensive turnkey solution for end-of-line operations.

Standard Features

- Shafted unwind stand.

- Tension control incorporate with dancer roll.

- Pneumatic cutters.

- Trim waste air blower.

- Top rider roller.

- Finished roll pusher.

- Auto cross cutting device.

- Manual unload cart.

- PLC control system incorporate with HMI touch screen.

- Enhanced unwind stand.

- Splice device.

- Motorized web threading.

- Auto. Knife positioning.

- Driven top rider roll.

- Semi-auto. shaft handling system.

- Motorized unloading cart.

- Enhanced fencing & safety implements.

- Finished roll bundling and weighing system.

- Finished roll conveying and palletizing .

- Increased efficiency and productivity

- Precise and accurate cutting for consistent quality

- Customizable options to meet specific needs

- Advanced automation features to reduce waste and improve output

| Roller width | 2000 – 6000 mm |

|---|---|

| Unwind diameter | 1200 / 2500 / 3000 mm |

| Min. slit width | 50 mm and up |

| Rewind diameter | 800 / 1500 / 3000 mm* |

| Machine Speed | 600 / 800 / 1000 M/min* |

* Speed and rewind diameter depend on material properties.

550x275_pic.jpg)

We are pleased to announce that we have recently shipped a Nonwoven Slitter Rewinder Model EG-2001G to a leading US manufacturer of nonwovens products. This nonwoven slitter rewinder is going to join their spunlace production line used in consumer or industrial to meet increasing market demands and is expected to have this machine put into production in Q1 2024.

Country : Japan

Model : EG-SR180S (EG-SR Series)

Country : Japan

Model : EG-1