Nonwoven Master Winder

• Meltblown nonwovens

• Airlaid nonwovens

• Spunlace nonwovens

• Spunbond nonwovens

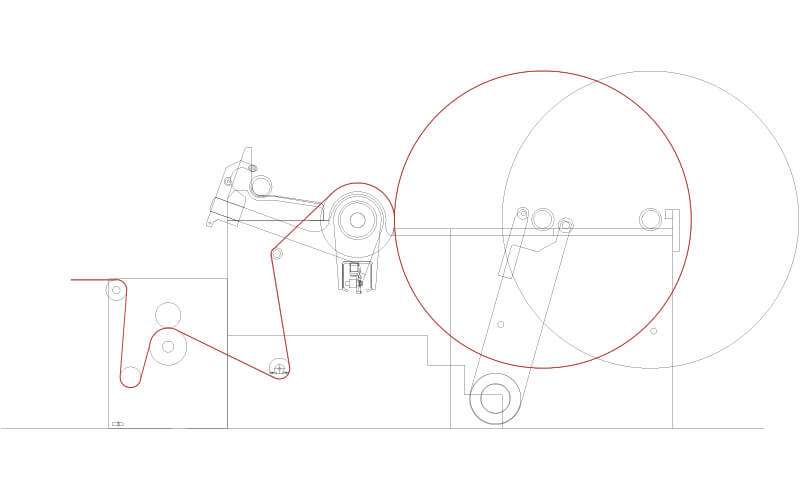

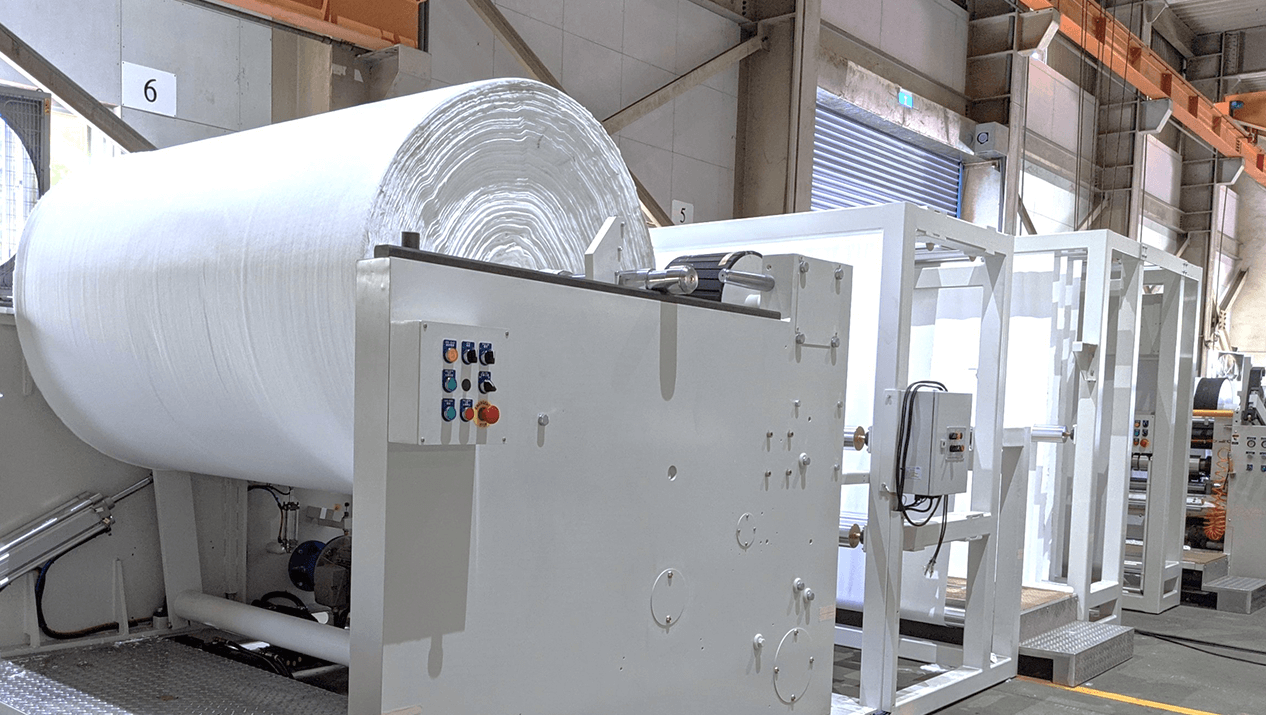

EG-SR In-line master winder is a high reliable master roll winder capable of integrating with clients’ nonwoven upstream line for a seamless production. This master roll winder features flying splice, master roll handling system, and an inline slitting that is an add-on for different winding configuration.

Standard Features

- Surface winding design.

- Load cell tension control.

- Driven drum roll with rubber coating.

- Spreader roller.

- Automatic roll taking-off.

- Automatic flying splice.

- PLC control system incorporate with HMI touch screen.

- Slitting function.

- Trim handling device.

- Extended finished roll storage.

- Shaft handling system.

- Enhanced fencing & safety implements.

| Roller width | 1100 – 5800 mm |

|---|---|

| Max. Rewind diameter | 2400 mm* |

| Max. Machine speed | 450 M/min* |

* Speed and rewind diameter depend on material properties.

550x275_pic.jpg)

We are pleased to announce that we have recently shipped a Nonwoven Slitter Rewinder Model EG-2001G to a leading US manufacturer of nonwovens products. This nonwoven slitter rewinder is going to join their spunlace production line used in consumer or industrial to meet increasing market demands and is expected to have this machine put into production in Q1 2024.

Do you know that the slitter rewinder is an essential machine in the converting industry? Its strategic design facilitates the efficient slitting and rewinding of large rolls of material, enabling their transformation into smaller and more specific sizes rolls. These machines assume a key role in various sectors such as packaging, printing, converting, and material processing. The purpose of this guide is to provide you with a thorough understanding of slitter rewinders, empowering you to make informed decisions when it comes to investing in or operating them.

Country : Japan

Model : EG-1

Country : Japan

Model : EG-SR180S (EG-SR Series)