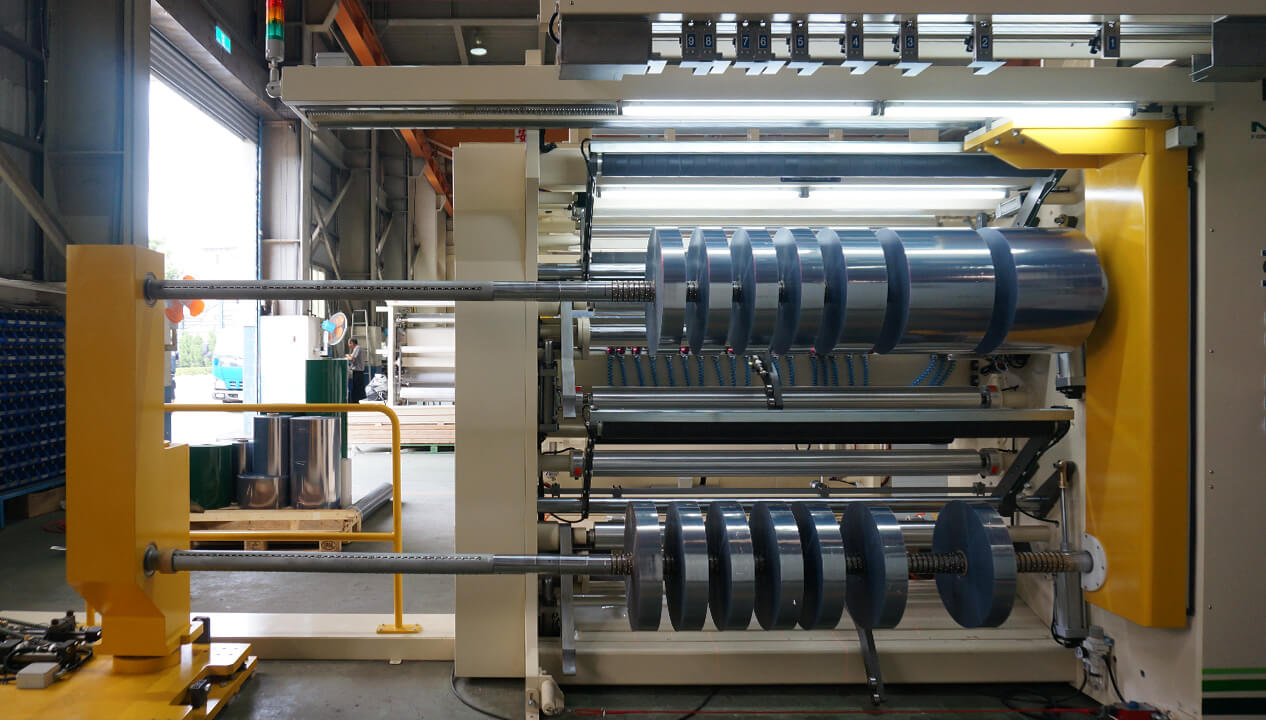

Duplex Shaft Center Winding Slitter Rewinder

• PSA , film & paper labelstock

• Liner-less thermal papers

• Coated, uncoated paper

• Pharmaceutical materials

• Aluminum lamination

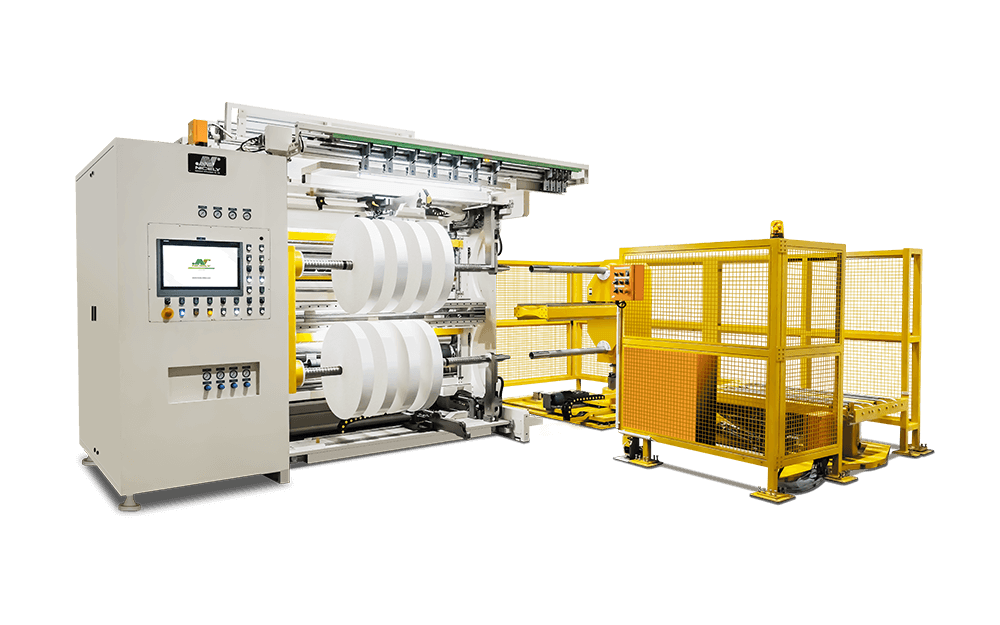

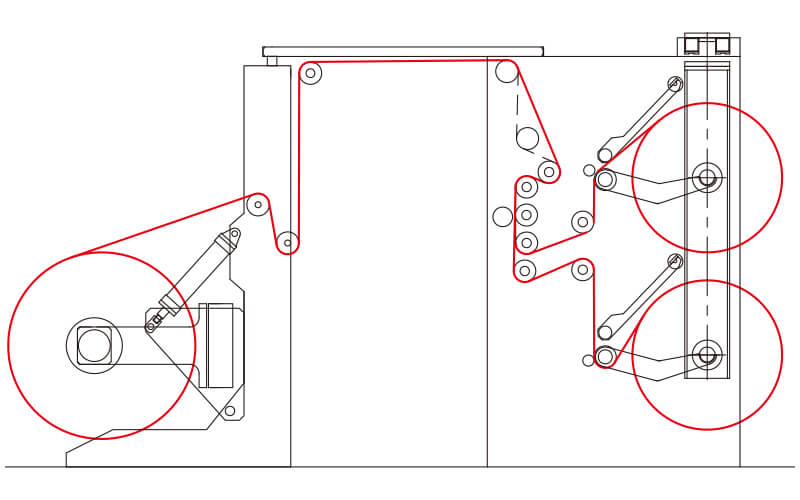

The EG-7008 series is a popular and highly sought-after model in the self-adhesive and PSA label industries. It is known for its exceptional features that enhance the overall experience. With an anti-telescoping device at the unwinder, a knife clean device, and a finish reel push-out device, this series ensures a smooth and convenient interface for operators. Moreover, the unloading system is designed to seamlessly transition from a vertical to a horizontal position, and it offers the added advantage of self-rotation, enabling efficient packing solutions.

Standard Features

- Shaftless unwind stand.

- Overhead or underneath web path.

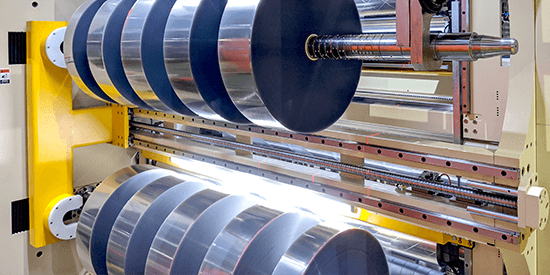

- Shear or razor cutters.

- Trim removal system.

- Pressure contact roller.

- Motorized finished roll pusher.

- Manual unloading unit.

- PLC control system incorporate with HMI touch screen.

- Shaftless unwind stand.

- Overhead or Underneath web path.

- Shear or razer cutters.

- Trim removal system.

- Pressure contact roller.

- Motorized finished roll pusher.

- Manual unloading unit.

- PLC control system incorporate with HMI touch screen.

- Splice device.

- Inspection lightbox.

- Motorized web threading.

- Pneumatic cutters.

- Auto. knife positioning.

- Differential rewind shafts.

- Laser-assisted core positioner.

- Motorized unloading system.

- Trim waste winder.

- Enhanced fencing & safety implements.

- Finished roll bundling, weighing, conveying, and palletizing system.

| Roller width | 1000 – 2300 mm |

|---|---|

| Unwind diameter | 800 mm – 1500 mm |

| Min. slit width | 50 mm and up |

| Max. rewind diameter | 800 mm |

| Machine speed | 300 / 500 / 800 M/min |

* Other specifications are offered at request.

In 2023, manufacturers worldwide experienced lower-than-expected economic conditions, with stagnant market inventories and hindered investment momentum. Notably, the only accelerating trend is the global demand for environmental sustainability and carbon reduction.

Flexible packaging is fundamental in providing protection and enhancing the visual appeal of consumer products. Central to the operations of this industry is the slitting process for flexible plastic films—which is a mechanism that significantly influences the efficiency and quality of the output.Integrated Solution