Duplex Center Winding Slitter Rewinder

• Films, CPE, CPP, APET, PET, PP, PA, PVC, BOPP, PU, LDPE, OPP, HDPE, MDPE, Nylon, TPU

• Plain, embossed PET, Optical PET

• Breathable/Non-breathable PE

• Rigid PVC

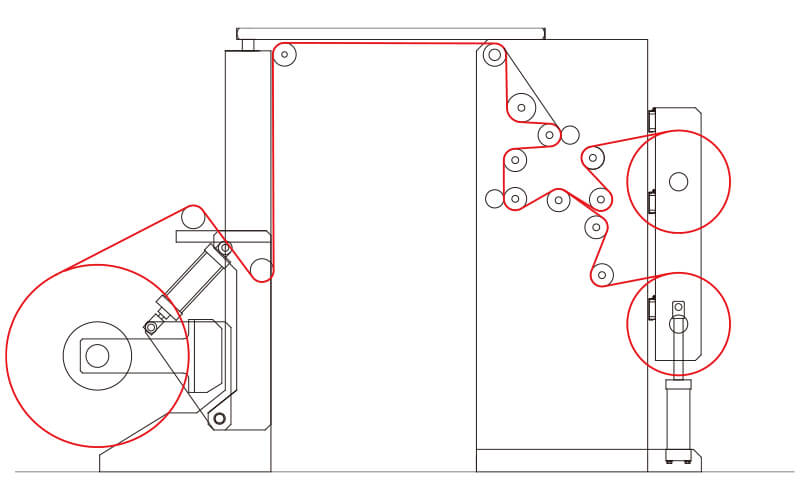

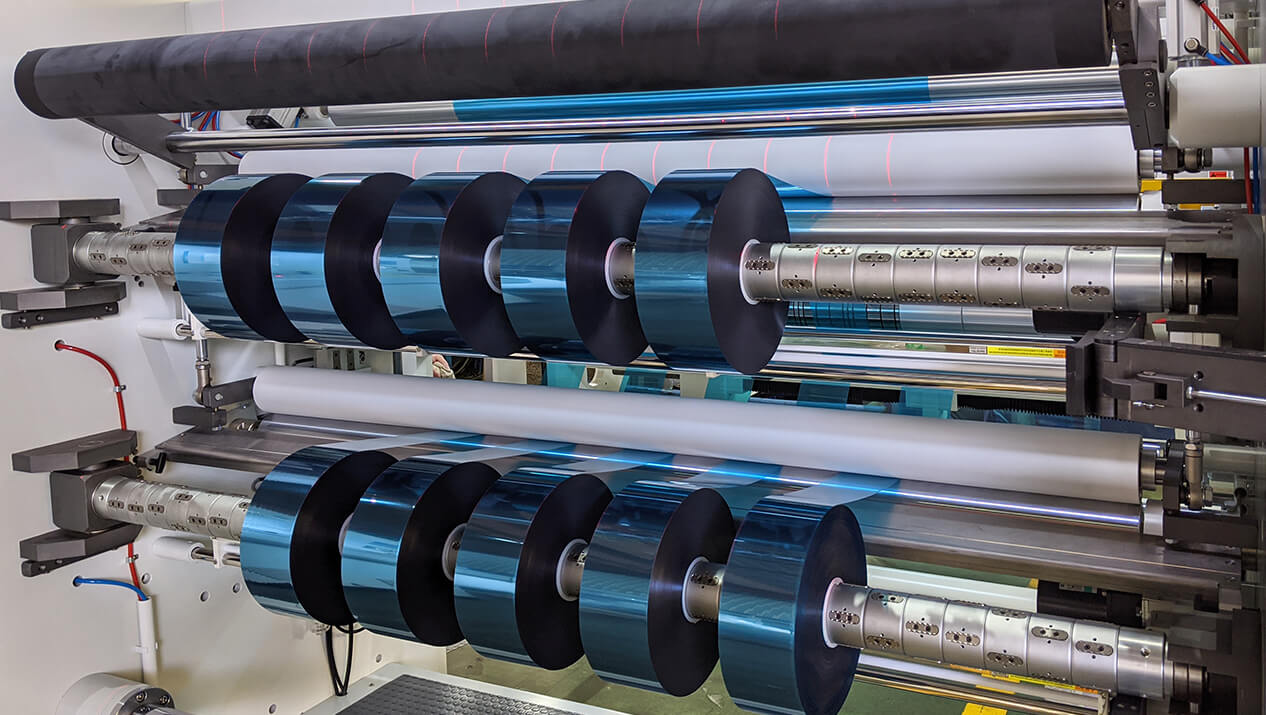

The EG-7003 series is a dual-shaft center winding slitter rewinder specifically designed for slitting various film-based composite materials. The series is categorized based on rewind sizes, with EG-7003A and EG-7003B featuring a rewind diameter of 450mm, and EG-7003D capable of reaching a rewind diameter of 600mm. These machines are widely used in the flexible packaging industry and offer optional automation, driving control, and unloading methods to meet increased production capacity requirements.

For processing larger diameter materials, the EG-7003A is a cost-effective and flexible option. It is commonly used not only in flexible print packaging but also for optical films and functional thin films.

The EG-7003B series offers the advantage of integrated unwinding and rewinding processes. Besides its extensive application in the packaging industry, it is frequently adapted for slitting circuit board-related materials. The machine's structure can be adjusted to meet customer-specific requirements while ensuring ease of operation.

Standard Features

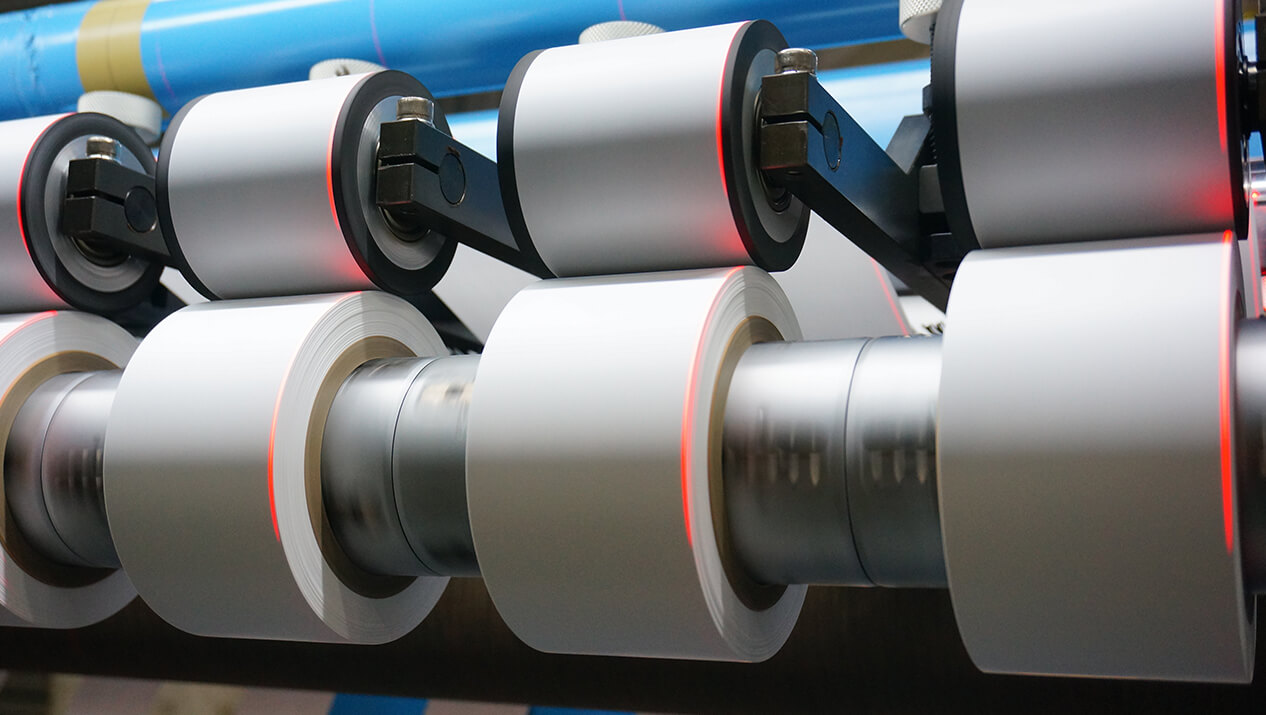

- Shear, score, or razor slitting.

- Trim removal system.

- Air expansion shafts.

- Static eliminator.

- Contact roller.

- Swing-out rewind shafts.

- Auto tension control.

- Manual unloading system.

- PLC control system incorporate with HMI touch screen.

- Splice device.

- Inspection lightbox.

- Pneumatic cutters.

- Auto. Knife positioning.

- Motorized finished roll pusher.

- Laser core positioner.

- Different rewind shafts.

- Trim waste winder.

- Customized solutions for roll handling.

- Enhanced fencing & safety implements.

| Roller width | 600 – 2200 mm |

|---|---|

| Unwind diameter | 800 mm – 1200 mm |

| Min. slit width | 50 mm and up |

| Max. rewind diameter | 450 mm |

| Machine Speed | 200 / 300 / 400 M/min |

* Other specification is offered at request.

Date: Oct 26 - 28, 2022

Add: No.1, Jingmao 2nd Rd., Nangang District, Taipei City 11568, Taiwan

Booth No.: N-023

Country : Taiwan Branch (Parent company in Japan)

Model : EG-7003DN (EG-7000 series)