Spooling Slitter Rewinder

EG-9000 series

• Film laminations

• Glass Fiber laminations

• Press Paper

• Mica tape for wire & cable

• Cover tape

• Carrier Tape

• Masking Tape / Hot Melt Tape

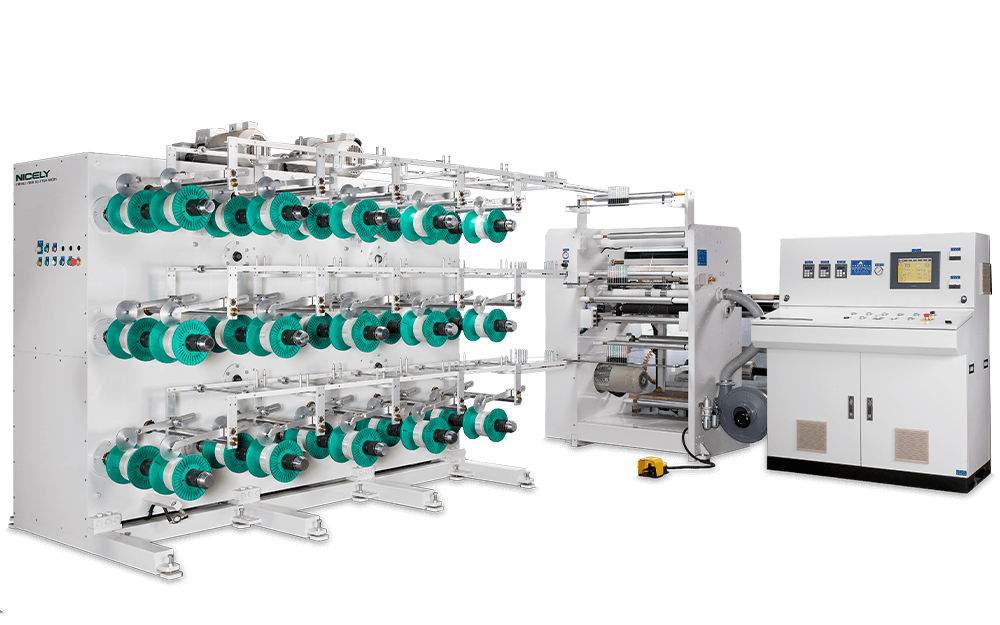

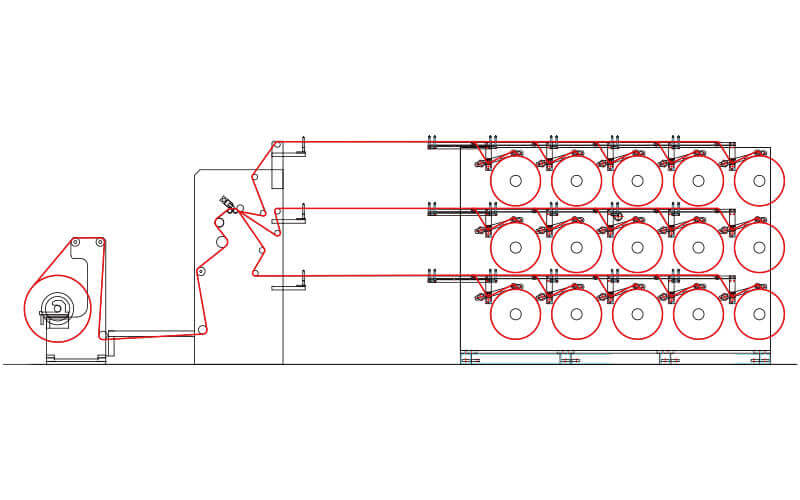

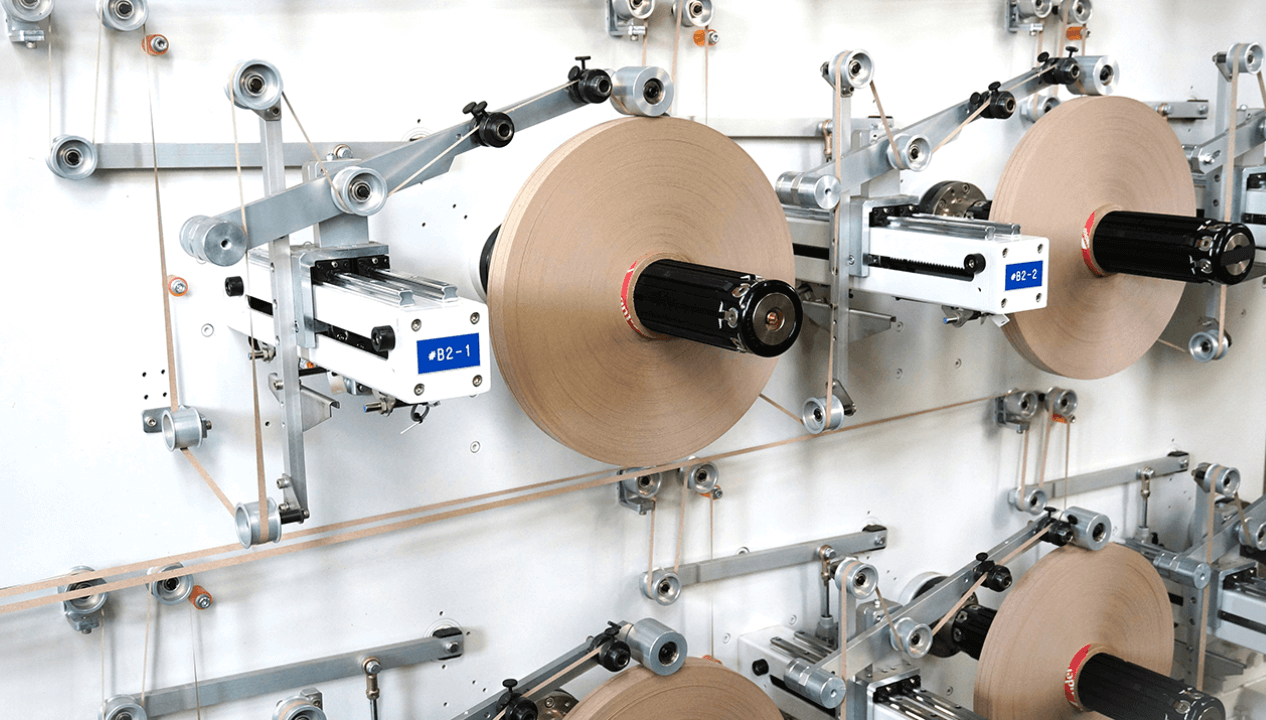

The EG-9000 series spooling slitter rewinder offers remarkable versatility with its winding options and demonstrates excellent performance in handling various materials. This spooling slitter rewinder also provides unparalleled flexibility, allowing customers to achieve disc winding (pancake) using other Nicely's integral models and add a spooling line for narrower spooling winding as needed.

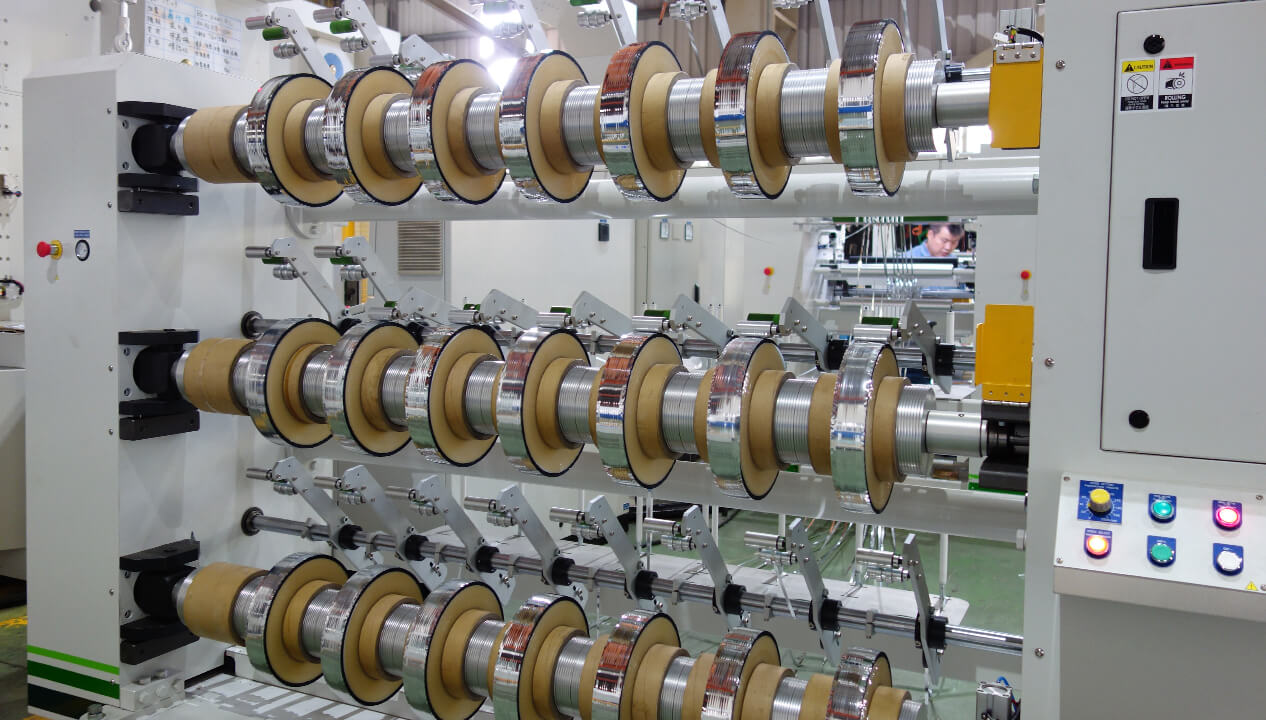

Featuring a minimum slitting width of 2mm and a modular design, it effortlessly expands from a basic set of 6 spools to meet the specific requirements. Additionally, the spooling slitter offers versatile winding patterns, including traverse, taper, stag, and flanged winding, ensuring optimal handling of insulation materials.

Electrical Insulations Application

The Nicely EG-9000 Spooling Slitter Rewinder is highly regarded among international customers in the insulation materials industry for its exceptional mica tape slitting and rewinding technology.

The durability and functionality of high-tech components such as electrical generators, transformers, electric motors, and energy storage systems depend on the properties of insulation materials. Materials like mica tape, insulation boards, and PI insulation films possess critical characteristics such as high strength, flexibility, and heat resistance, making them the preferred choice for high-voltage applications.

Read more about EG-9000 Series : Boost Efficiency with Narrow-Slit Spooling Technology : EG-9000 series Spool Slitter Rewinder

Flexible Packagings Application

Featuring a minimum slitting width of 2mm and a modular design, it effortlessly expands from a basic set of 6 spools to meet the specific requirements. Additionally, the spooling slitter offers versatile winding patterns, including traverse, taper, stag, and flanged winding, ensuring optimal handling of insulation materials.

Electrical Insulations Application

The Nicely EG-9000 Spooling Slitter Rewinder is highly regarded among international customers in the insulation materials industry for its exceptional mica tape slitting and rewinding technology.

The durability and functionality of high-tech components such as electrical generators, transformers, electric motors, and energy storage systems depend on the properties of insulation materials. Materials like mica tape, insulation boards, and PI insulation films possess critical characteristics such as high strength, flexibility, and heat resistance, making them the preferred choice for high-voltage applications.

Read more about EG-9000 Series : Boost Efficiency with Narrow-Slit Spooling Technology : EG-9000 series Spool Slitter Rewinder

Flexible Packagings Application

Widely used in low-adhesion packaging materials, chip paper tape, narrow textile bands, masking tape, label paper, and other fields. These machines provide precise slitting, consistent tension control, and optimal rewinding, enabling manufacturers to meet the growing demand for consumer goods packaging.

- Shafted unwind stand.

- Shear, score slitting.

- Trim removal system.

- Auto. tension control.

- PLC control system incorporate with HMI touch screen.

Optional Features

- Shaftless unwind stand.

- Splice device.

- Different rewind shafts.

- Trim waste winder.

- Enhanced fencing & safety implements.

| Roller width | 600 mm |

|---|---|

| Unwind diameter | 1200 mm |

| Min. slit width | 2 mm and up |

| Max. rewind diameter | 450 mm |

| Traverse range | 250 mm |

| Machine speed | Max. 300 M/min. |

* Other specifications are offered at request.

Question ? Ask us !