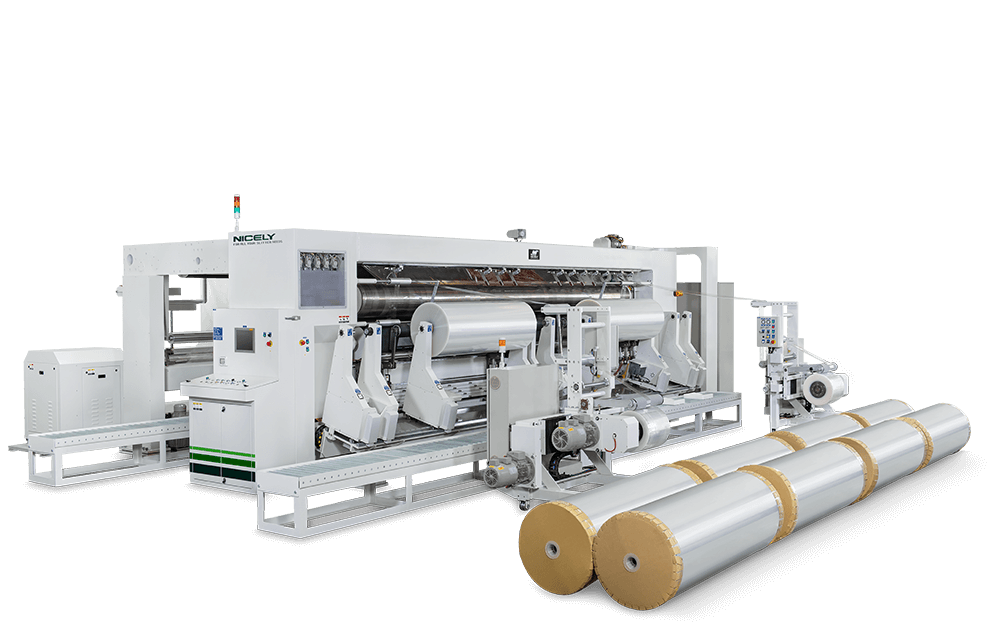

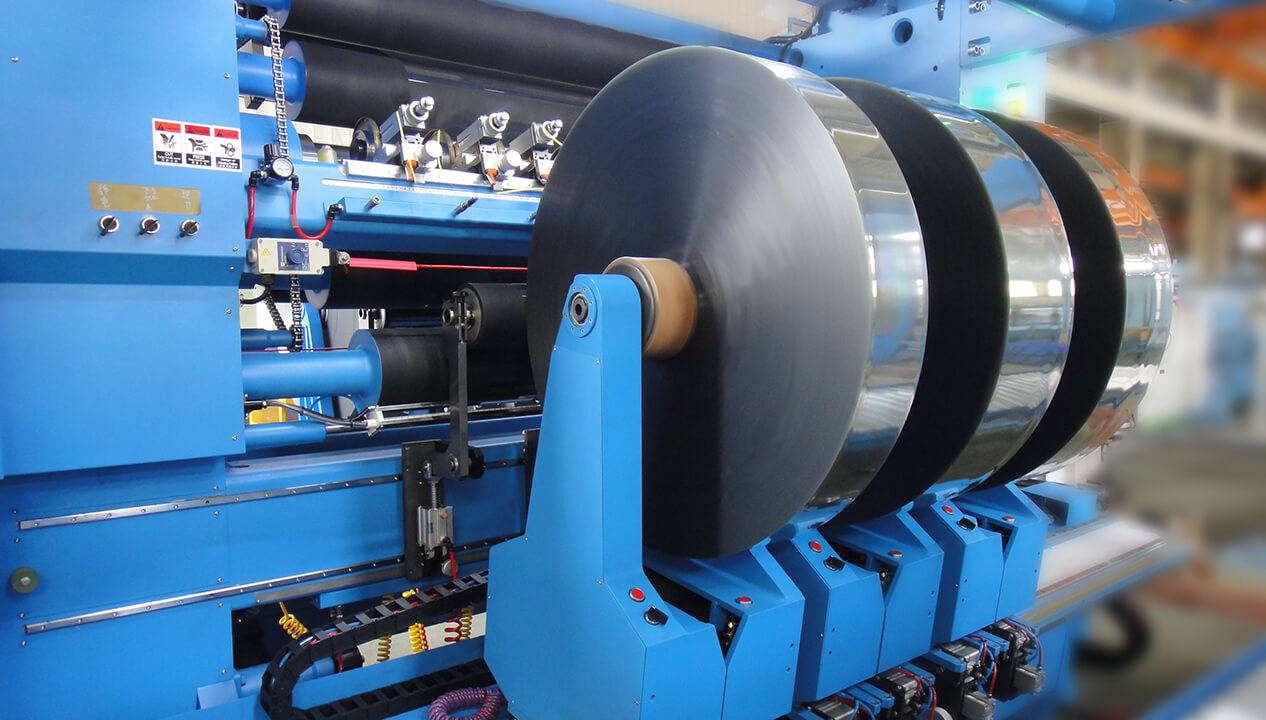

Primary Slitter Rewinder

Materials:

• Films, BOPP, BOPET, BOPA, PE, PET, PS, PP, PVC,

CPP, CPE, OPP (Plain / Metalized / Shrinkable / Rigid)

• LDPE / Nonwoven / Laminations

• Acrylic adhesive

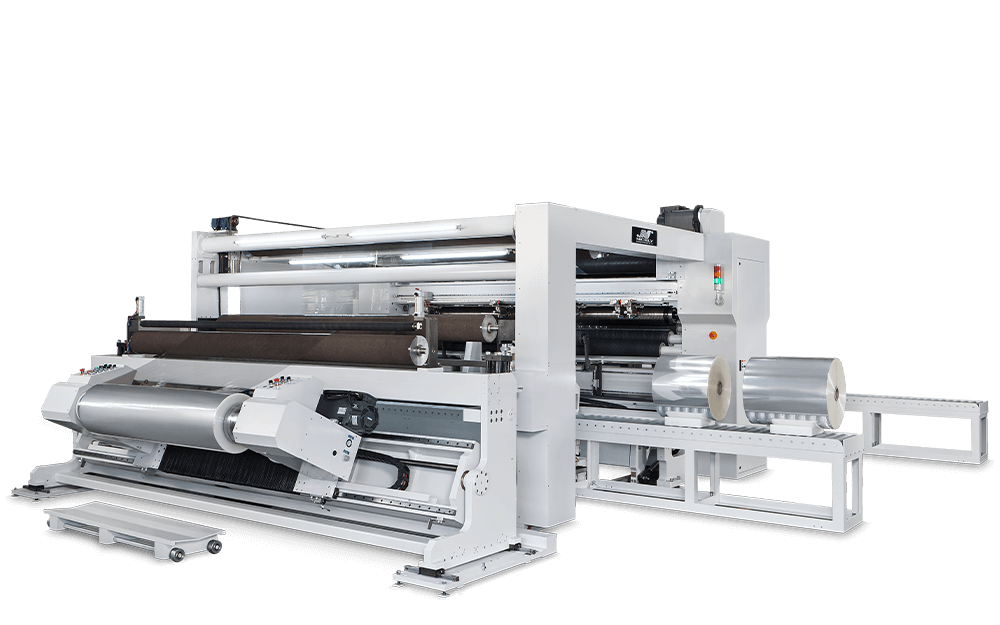

In addition to our new primary slitter, Nicely Machinery is renowned for its expertise in retrofitting other-brand primary slitters. This retrofitting service provides customers with the opportunity to increase productivity and efficiency while making a reasonable investment.

Standard Features

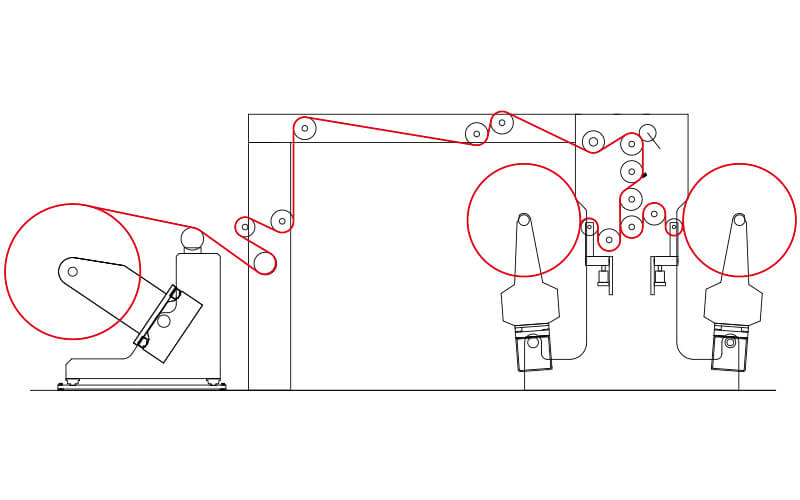

- Shaftless unwind stand.

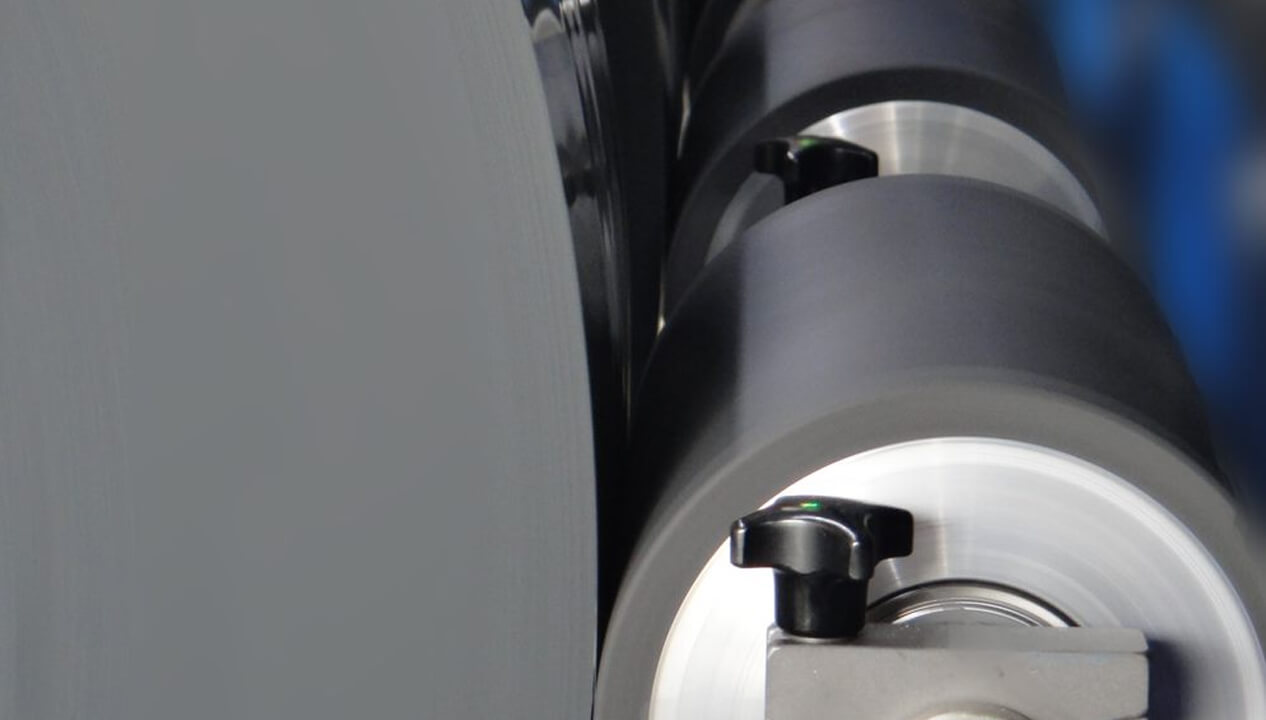

- Shear or razor cutters.

- Individual winder.

- Trim waste winder.

- Manual unloading cart.

- Spreader roller.

- PLC control system incorporate with HMI touch screen.

- Splice device.

- Inspection lightbox.

- Motorized web threading.

- Auto. Knife positioning.

- Dust remover.

- Auto. winder positioning.

- Motorized unloading system.

- Electrical actuator system.

- Enhanced fencing & safety implements.

| Roller width | 1500 - 7800 mm |

|---|---|

| Unwind diameter | 1000 / 1500 mm |

| Min. slit width | 300 mm and up |

| Max. rewind diameter | 1200 mm |

| Machine speed | 400 / 600 / 800 M/min |

* Other specifications are offered at request.

Investing in a slitting and rewinding machine can be done in two ways : buying a new machine or retrofitting an existing one. Each option has its own pros and cons.

Nicely Machinery provides retrofitting and upgrading services for customers who have older slitter rewinders, whether machines were originally from Nicely or another supplier.

Nicely is currently having one primary slitter in the facility features 5.8 meters in machine roller width and with the output diameter up to 800mm.This slitter rewinder is sold to our existing customer who is one of the renowned BOPP suppliers in northern city of Taiwan and is scheduled to be delivered and began the production run in September.

_pic.jpg)